Through powerful mixing techniques, flotation residues (tailings) that still contain large amounts of valuable substances can be economically disposed of. In order to recover recyclable materials, the residual material must usually be mixed with one or more other materials and made into pellets.

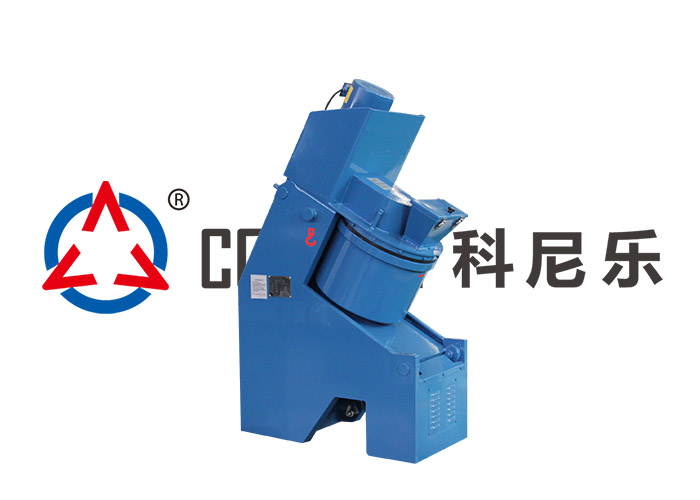

CR05 Intensive granulating mixers can handle all types and concentrations of materials without any problems, for example, by adding dry materials to produce pellets from sludge. The clumps are well broken down and the final product exhibits a very high blend quality.

CONELE offers a full range of mixing equipment, from the small CEL1s laboratory mixer machine to the large CRV33 industrial machine, supporting various binder systems including ceramic, resin, and metal, and suitable for various abrasives such as corundum

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.