CO-NELE Refractory Mixers Machine can provide special experience and expertise in these product areas:

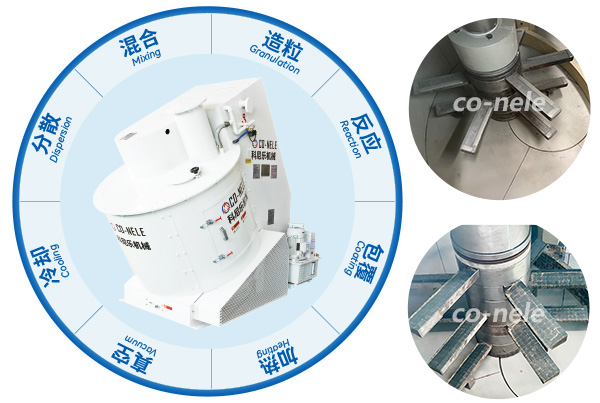

| Planetary Mixers for Refractory CO-NELE refractory mixer operates in a planetary manner, quickly mixes various refractory materials, has high efficiency, mixes evenly without dead corners, and is automated, making it easy to arrange in various refractory production lines. |

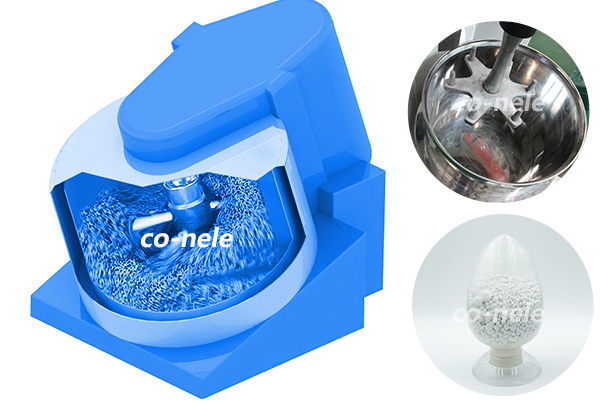

| Intensive Mixers for Refractory CO-NEEL refractory material strong mixer can operate according to the countercurrent or cross-flow principle, quickly mix and granulate, with high mixing uniformity, high ball formation rate, automatic production, and flexible application in various refractory material production lines. |

| Intensive Mixers for Refractory Granulation Preparation CO-NEEL refractory material strong mixer can operate according to the countercurrent or cross-flow principle, quickly mix and granulate, with high mixing uniformity, high ball formation rate, automatic production, and flexible application in various refractory material production lines. |

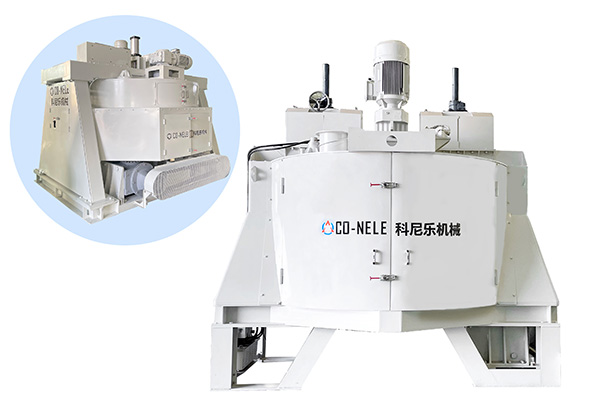

| Pressure-regulated lifting type wheel roller high-speed Refractroy mixer CO-NELE pressure-adjustable lifting high-speed roller mixer is a high-end mixing equipment designed by our company for the ceramic and refractory industries. The mixed materials are uniform, efficient, and have no dead angles. The mixed materials have high density and small pores. The pressure-adjustable lifting system is designed, which can flexibly adjust the pressure, lift the roller, form a pressure-maintaining overflow function, and has a high degree of automation, which greatly improves production efficiency. Mixing volume: 0.3T-2T |

CO-NELE Refractory Mixers Machine Case

Unshaped refractory materials

Unshaped refractory materials(also known as bulk refractory materials)refer to refractory materials that can be directly constructed by pouring,ramming,spraying,etc.without high-temperature sintering and forming.They are characterized by strong flexibility and convenient construction.

Castables

Composition:aggregate(such as high-alumina bauxite,corundum)+fine powder(such as alumina micropowder)+binder(calcium aluminate cement,sol).

Features:good fluidity,can be cast into complex shapes,and need to be mixed with water before use.

Application:blast furnace iron ditch,electric furnace top,cement kiln mouth.

Subdivision type:

Low cement castable(LCC):cement content<8%,high temperature strength.

Self-flowing castable:no vibration is required,and the gap is automatically filled.

Anti-explosion castable:add explosion-proof fiber(such as stainless steel fiber).

Ramming Mixes

Composition:coarse-grained aggregate+binder(phosphoric acid,resin).

Features:Needs mechanical or manual compaction,low porosity,strong corrosion resistance.

Application:Induction furnace lining,blast furnace bottom,iron ladle working layer.

Gunning Mixes

Composition:Similar to castables,but with finer particle size.

Features:Rapidly repair kiln linings by spraying with a gun wet/dry method.

Application:Repair of converters,ladles,and hot air ducts.

Plastics

Composition:soft clay+aggregate+plasticizer(such as lignin).

Features:High plasticity at room temperature,directly rammed or extruded.

Application:Heating furnace roof,soaking furnace lining.

Refractory Mortars

Composition:fine powder(matching the main material)+binder(water glass,phosphate).

Features:Used for masonry joints of shaped products,high temperature resistant bonding.

Types:Siliceous mud,high-alumina mud,magnesia mud,etc.

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.