Li-lon Intensive Mixer can be applied to lithium cobaltate, lithium nickelate, lithium manganate, lithium iron phosphate (ternary), lithium titanate, graphite, electronic materials, chemical materials, etc. The quality of the electrodes affects the performance of the battery. Efficient preparation of electrode mixtures (slurry, plastic body, or dry mixes) is an important task.

Benefits of the unique CONELE hybrid system:

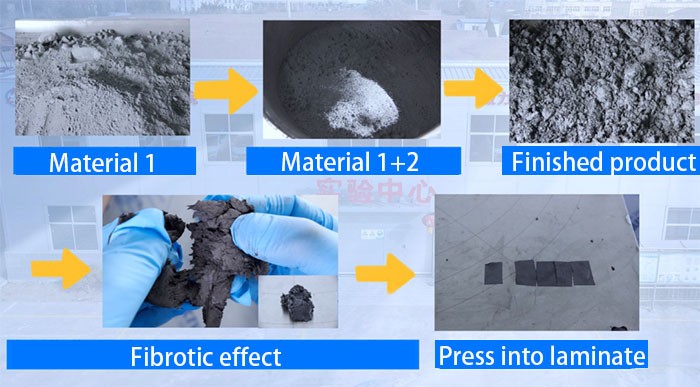

The mixing, dispersion, granulation, surface treatment and surface coating of raw materials can be completed with 1 equipment!5. Achieve the best dry mixing, wrapping and fibrosis effect in a short time

CONELE Intensive mixer with inclined mixing pan for mixing, granulating, plasticizing/kneading and coating. In the production of lithium-ion batteries, this intensive mixer can be used just as well for preparing raw materials as for processing electrode dry mixes or wet mixes.

| CEL01-10 Lab Li-lon Intensive Mixer Outout Capacity:1-10L Input Capacity:1.5-15L Function: mixing granulating/plasticizing/kneading/coating Auxiliary functions: heating/cooling/vacuum |

| CR02-08 Lab Li-lon Intensive Mixer Outout Capacity:5-50L Input Capacity:7.5-75L Function: mixing granulating/plasticizing/kneading/coating Auxiliary functions: heating/cooling/vacuum |

| CR09-15 Li-lon Intensive Mixer Outout Capacity:100-350L Input Capacity:150-525L Function: mixing granulating/plasticizing/kneading/coating Auxiliary functions: heating/cooling/vacuum |

| CRV15-24 Li-lon Intensive Mixer Outout Capacity:500-2000L Input Capacity:750-3000L Function: mixing granulating/plasticizing/kneading/coating Auxiliary functions: heating/cooling/vacuum |

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.