LATEST NEWS & CASES

CR05 Intensive granulating mixers can handle all types and concentrations of materials without any problems.

Intensive Mixer for Mixing Lithium Battery Slurry

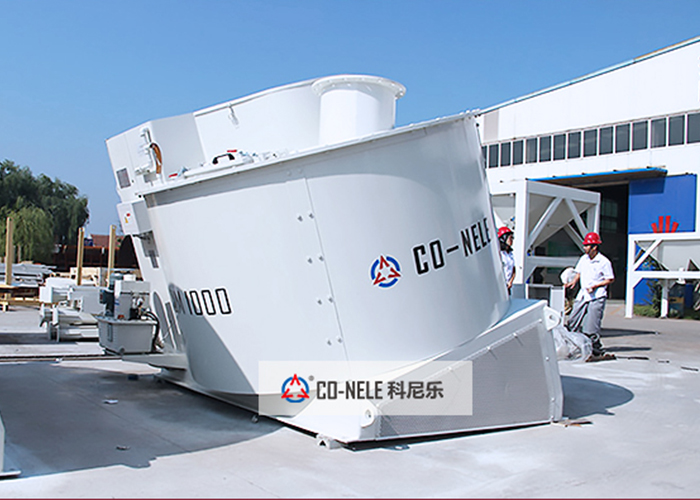

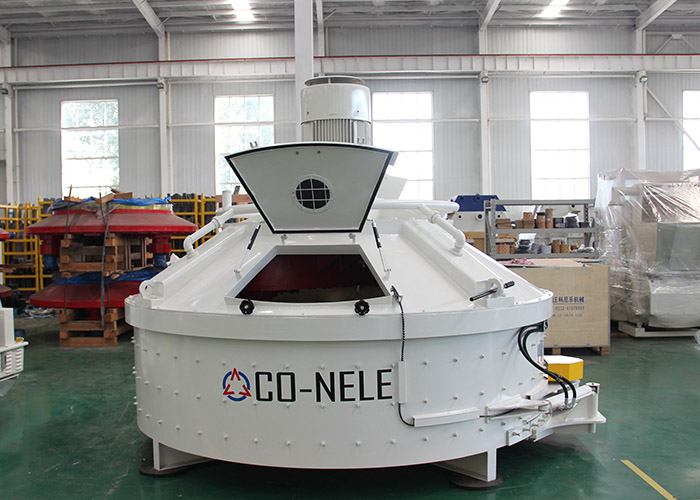

Concrete Planetary Mixer for Brick Making Machine - CONELE

Intensive Mixer for Granulate/Pelletizing Technology

Planetary Concrete Mixer Manufacturers for Mixing UHPC

What Are the Reasons to Choose CONELE Intensive Mixer

Intensive Granulator for Ceramic Powder 750ltr/batch

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.