LATEST NEWS & CASES

As 3D printing advances into more precise and complex applications, CONELE remains committed to innovating material preparation equipment and driving industry transformation.

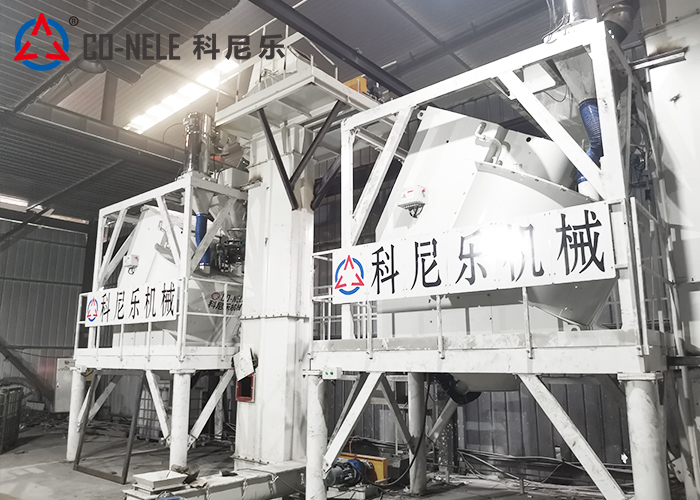

Refractory Material Mixing Equipment Designed by CO-NELE Demonstrates High Efficiency and Homogeneity in Refractory Preparation

By carefully selecting and operating CONELE refractory granulation mixer, manufacturers can produce high-quality mullite crucibles that meet the demanding requirements of various industrial applications.

Practical application cases show that the use of high quality UHPC concrete mixer can significantly improve the production efficiency and quality of UHPC.

The CR08 ceramic materials intensive mixer is a state-of-the-art solution for the efficient and uniform mixing of silicon carbide and other ceramic materials.

Refractory materials for making industrial saggers include mullite, corundum mullite, alumina, etc. This refractory intensive mixer for sagger is developed to produce a homogeneous mixture in a short mixing time.

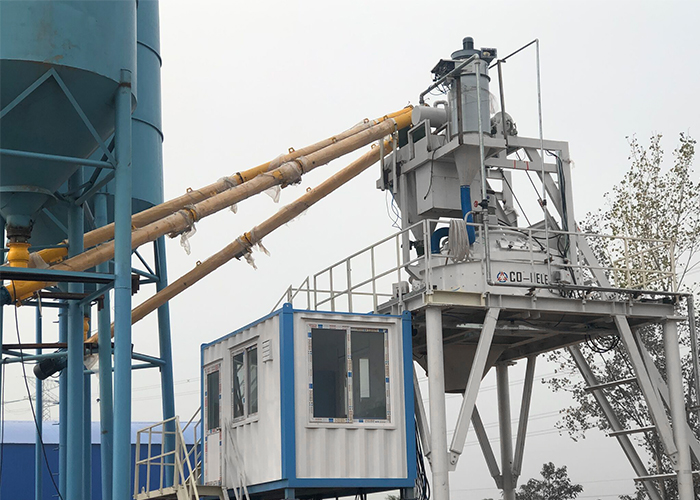

CONELE has made a new design for the main machine of the concrete mixing station to enhance the production quality of the cement pipe, and the blade material and liner clearance of the mixer are designed according to the mixing requirements. The special c

The intensive refractory mixer can significantly improve the production efficiency of magnesia carbon brick through powerful mixing.

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.