This is the core equipment, which is responsible for fully mixing cement, sand, gravel, water and various additives according to the set ratio. It has good mixing effect and high efficiency, can make the various components of concrete evenly distributed, and ensure the stability of concrete quality.

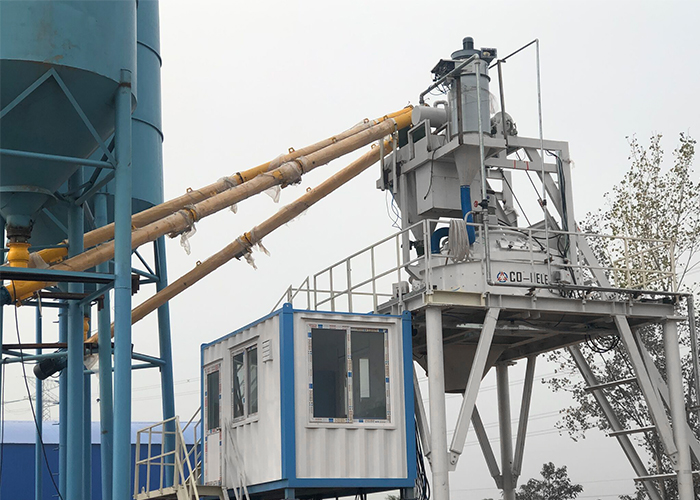

CONELE has made a new design for the main machine of the concrete mixing station to enhance the production quality of the cement pipe, and the blade material and liner clearance of the mixer are designed according to the mixing requirements. The special concrete mixing plant of CONELE cement pipe improves the quality of the production of cement pipe.

Usually, there are also accurate metering devices, such as electronic scales, etc., to accurately weigh each raw material added to strictly control the mix ratio of concrete.

On the one hand, it is used to transport raw materials from the silo to the vertical axis planetary concrete mixer, and on the other hand, after the concrete mixing is completed, the finished concrete is transported to the designated storage or use location.

To address the need for highly homogeneous mixing and stable granulation in honeycomb zeolite production, this project selected the CO-NELE CRV24 honeycomb zeolite mixing and granulation machine as the core front-end process equipment.

CONELE intensive mixer can serve as core material processing equipment for environmental technology, supporting various processes ranging from industrial waste pretreatment, waste solidification, resource recovery, secondary fuel preparation to contaminat

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.