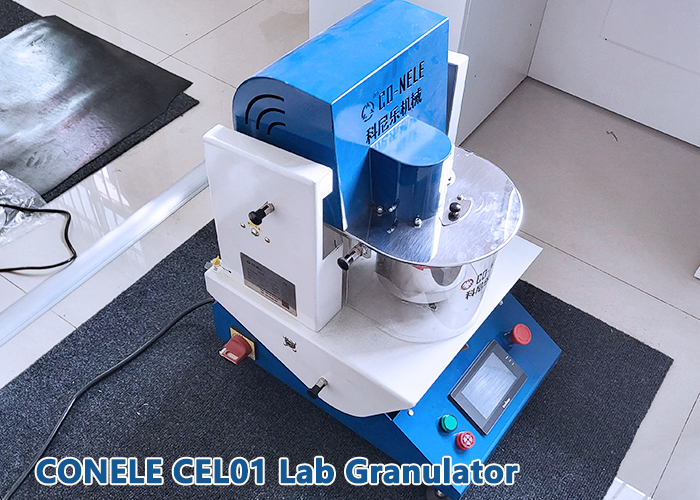

To address the need for highly homogeneous mixing and stable granulation in honeycomb zeolite production, this project selected the CO-NELE CRV24 honeycomb zeolite mixing and granulation machine as the core front-end process equipment.

CONELE intensive mixer can serve as core material processing equipment for environmental technology, supporting various processes ranging from industrial waste pretreatment, waste solidification, resource recovery, secondary fuel preparation to contaminat

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.