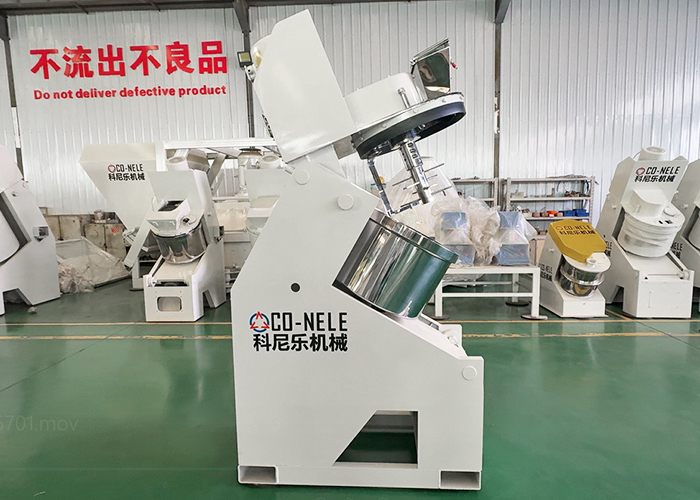

The laboratory intensive mixer is specially designed for lab-scale projects, with a compact size and mixing capacity that meets the needs of experiments, reducing material waste and producing results consistent with large-scale equipment.

The laboratory intensive mixer can fully mix powdered, granular, and viscous materials. At the same time, by adjusting the mixer's speed, time, and inclination angle, the particle size and strength can be precisely controlled.

The laboratory intensive mixer has a wide range of applications and can handle various material forms, including powders, granules, slurries, etc. In the catalyst, molecular sieve, welding materials and flux, lithium battery, fertilizer, chemical, and other industries, suitable applications can be found.

CONELE offers a full range of mixing equipment, from the small CEL1s laboratory mixer machine to the large CRV33 industrial machine, supporting various binder systems including ceramic, resin, and metal, and suitable for various abrasives such as corundum

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.