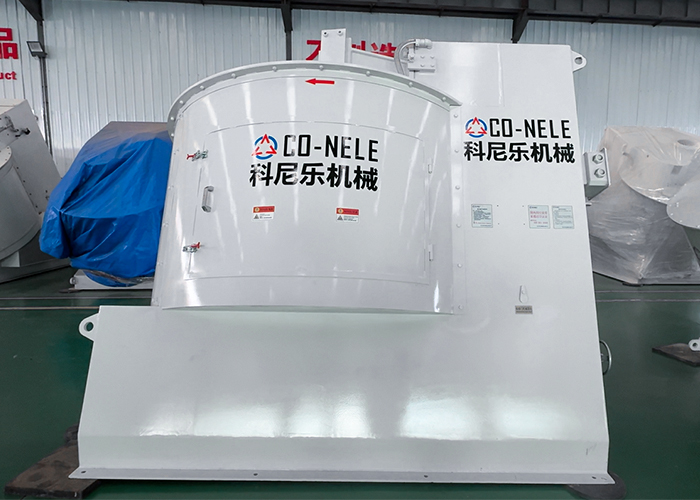

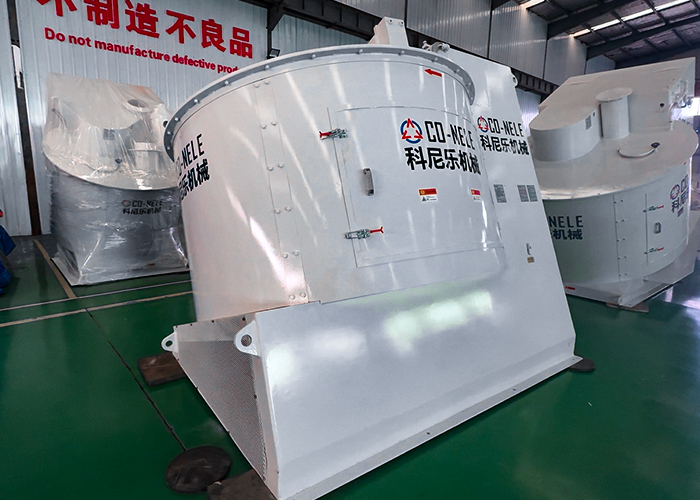

The CRV19 intensive mixer is a high-performance mixing solution designed for various industrial applications, including pelletizing and granulating processes. This advanced mixing technology ensures efficient and uniform blending of materials, enhancing the quality and consistency of the final product.

6. Safety: Designed with safety features including emergency stop mechanisms and protective guarding to ensure safe operation.

- Construction: Made from high-quality stainless steel and other durable materials.

.jpg)

Relying on the CO-NELE CR02 laboratory intensive mixing granulator (5 liters effective volume), through three batches of experiments, our technical team successfully granulated the raw material into uniform spherical particles with a particle size of 2-3

CONELE offers a full range of mixing equipment, from the small CEL1s laboratory mixer machine to the large CRV33 industrial machine, supporting various binder systems including ceramic, resin, and metal, and suitable for various abrasives such as corundum

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.