Intensive mixers are high-shear machines crucial for preparing ceramic bodies(tiles,sanitaryware,refractories,technical ceramics)by achieving homogeneous mixing and controlled granulation of powders,binders,liquids,and additives.They outperform simple tumble or paddle mixers in efficiency and quality for demanding ceramic processes.

Disadvantages:Higher initial investment,more complex mechanics than some horizontal mixers.

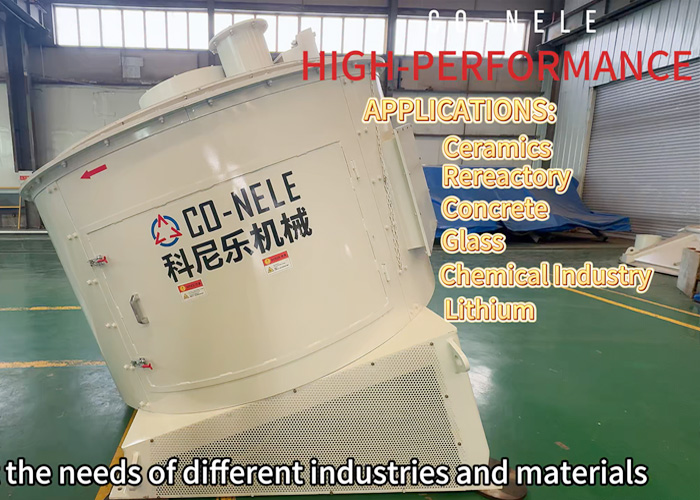

CONELE offers a full range of mixing equipment, from the small CEL1s laboratory mixer machine to the large CRV33 industrial machine, supporting various binder systems including ceramic, resin, and metal, and suitable for various abrasives such as corundum

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.