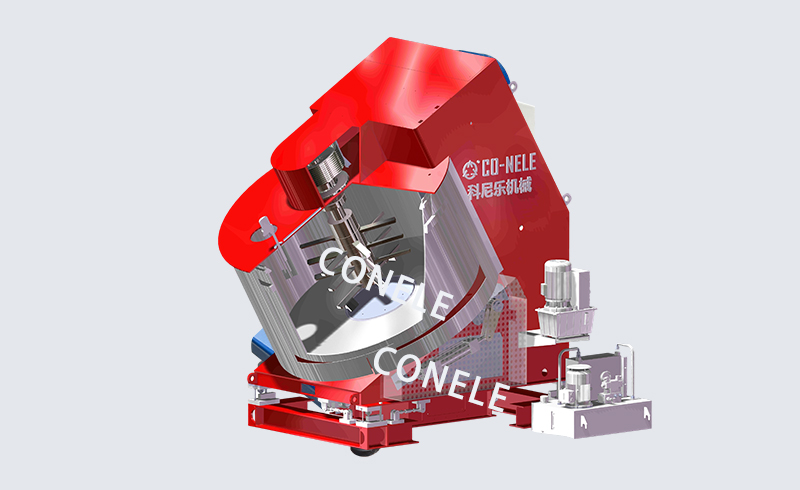

CONELE Bentonite Granulator employs advanced inclined high-intensity mixing and three-dimensional turbulent flow technology, providing an efficient and stable integrated solution for the homogenization, mixing, and granulation of bentonite. This granulator machine produces bentonite granules with uniform particle size, high sphericity, and excellent strength. It is widely used in foundry, drilling, iron ore pelletizing, cat litter, environmental protection, agriculture, and more. We offer a complete range of equipment from small-scale laboratory to large-scale continuous production, along with customized bentonite granules production line design.

A complete production line ensures efficiency and quality from raw material to finished product.

1. Raw Material Pre-treatment Section: Screening, crushing, and drying equipment to ensure raw material particle size and moisture meet requirements.

2. Batching and Mixing Section: Precise metering systems and high-efficiency mixers for uniform compounding of bentonite with binders, modifiers, and other additives.

3. Core Granulation Section: Selecting the most suitable Bentonite Granules Making Machine based on product characteristics (strength, shape, density).

Three-Dimensional Mixing Granulator (Recommended): Integrates mixing and granulation, ideal for products requiring high uniformity and sphericity.

Double-Roller Extrusion Granulator: A dry process that compacts powder directly into flakes or granules under high pressure, requiring no subsequent drying.

Rotary Drum Granulator / Disc Granulator: Forms granules through rolling agglomeration, suitable for high-volume standardized products.

Spray Granulator: Combines liquid atomization with powder, used for preparing specific microsphere-structured products.

4. Post-Granulation Processing Section:

Dryer: (Essential for wet processes) Removes excess moisture from granules.

Cooler: Cools granules for subsequent screening and packaging.

Screening Machine: Separates qualified granules; fine powder and oversized particles are returned to the system for reprocessing, ensuring high yield.

Coating Machine: (Optional) Applies a surface coating to granules for anti-caking, controlled release, or improved appearance.

5. Packaging and Environmental Protection Section:

Automatic Packaging System: Enables precise weighing and automated packaging of finished products.

Dust Removal System: Dust collection equipment at key points throughout the line ensures a clean production environment.

By adjusting the main unit's rotation speed, tilt angle, granulation time, and binder addition, the finished granule size can be flexibly controlled within a range of 0.5-10mm.

Excellent granulation results in round, high-strength granules with a tight particle size distribution, meeting the requirements of high-end applications.

Unique three-dimensional turbulent motion ensures thorough, homogeneous dispersion of materials (including main ingredients and micro-additives) throughout the entire vessel with no dead zones.

Key components utilize wear-resistant materials and reinforced design to withstand the highly abrasive nature of bentonite, ensuring long-term, stable operation and extended service life.

Industrial-scale models are designed for continuous, high-volume production and are the core equipment of the production line.

Offers various batch and continuous models suitable for different needs, from R&D and pilot-scale testing to large-scale industrial production.

High Capacity and Modularity: Covering a wide range of production capacity needs, the modular design allows for flexible configuration adjustments based on raw materials and output.

Micro-scale Operation and Flexibility: The minimum experimental material volume can be as low as 100 ml, and experimental parameters can be directly scaled up to the production stage.

Precise Control and Safety: Supports precise control of speed, time, and temperature, and the compact design facilitates safe operation in confined environments such as glove boxes.

Type | CR02 | CR04 | CR05 | CR08 | CR09 | CRV09 | CR11 | CR15 | CRV15 | CR19 | CRV19 | CR24 | CRV24 |

In capacity(L) | 7.5 | 15 | 37 | 75 | 150 | 225 | 375 | 525 | 750 | 1125 | 1500 | 2250 | 3000 |

Out capacity(L) | 5 | 10 | 25 | 50 | 100 | 150 | 250 | 350 | 500 | 750 | 1000 | 1500 | 2000 |

Mixing device | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

Paddle | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

CONELE CR02 Laboratory Clay Granulator Mixer...

CONELE CR02 Laboratory Clay Granulator Mixer...

If you have any questions, please leave a message, we will reply as soon as possible.

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.