Vertical Planetary Concrete Mixer Features

Co-nele vertical planetary mixer is innovatively developed based on synchronous German technology.

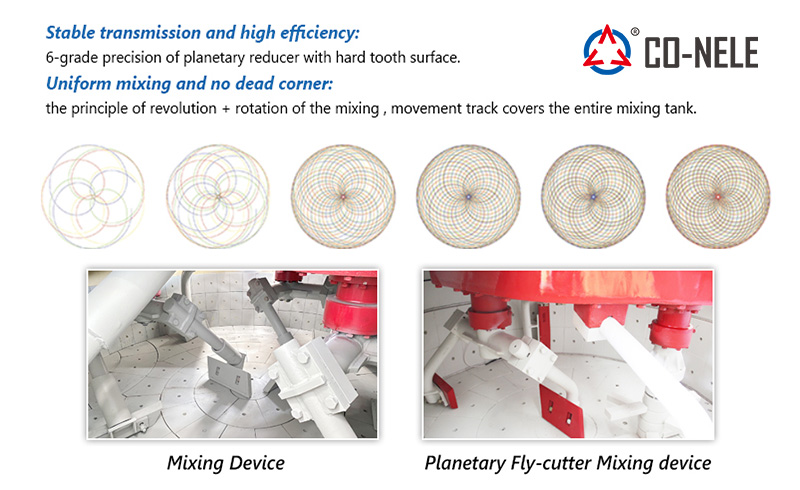

Smooth transmission and high efficiency: hardened gear reducer for transmission, low noise, high torque and strong durability.

Even mixing and no dead angle: the mixing blade revolution + rotation motion principle, the motion trajectory covers the entire mixing barrel.

Wide mixing range: suitable for mixing and mixing of various aggregates, powders and other special materials.

Easy to clean: high-pressure cleaning device (optional), spiral nozzle, large coverage area.

Flexible layout and fast unloading speed: 1-3 unloading doors can be flexibly selected to meet the needs of different production lines;

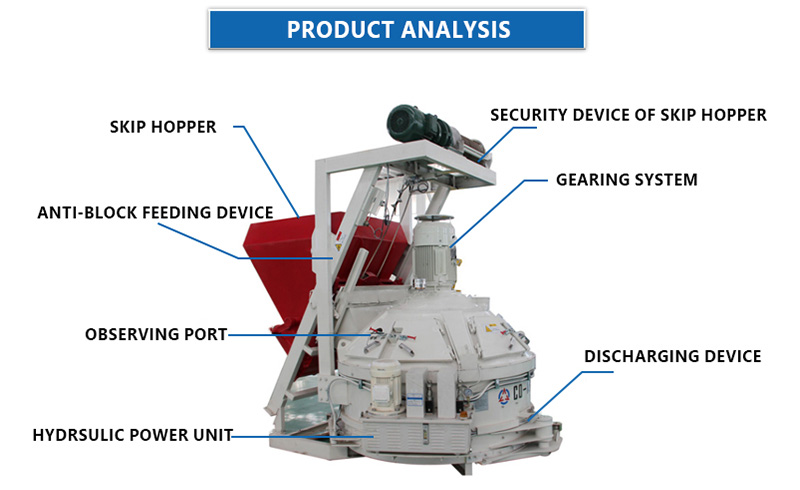

Easy installation and maintenance: large-size maintenance door, maintenance door with safety switch.

Diversified mixing devices: customized mixing devices according to customer needs.

Good sealing: no leakage problem.

Compulsory mixing is realized by composite moves of extruding and overturning driven by rotating planets and blades.

Mixing blades are designed in parallelogram structure(patented), which can be turned 180°for reuse to increase sewice life.Specialized discharge scraper has been designed according to discharge speed in order to increase productivity.

The movement of the material inside the trough is smooth and continuous.the blades track covers the whole bottom of the trough after a cycle.

Driving system consists of motor and hardened surface gear which is specialized designed by CO-NELE(patented). Flexible coupling and hydraulic coupling(option)connects motor and gearbox. The gearbox is designed by CO-NELE (completely independent intellectual property rights owned) absorbing European advanced technology. The improvedmodel has lower noise,longer torque and more durable.

Planetary mixer equipped with skip hoist and weighing system.The inlet will open and close automatically when skip hoist lift to the inlet or descend (Patent), preventing dust from coming out of mixer to a result of Environmental.Cement scale and water scale (Include precision measurement) are designed very reasonably. Weighing is more accurate.

According to the different demands of customers, the discharging door can be opened by hydraulic, pneumatic or by hands. The number of the discharging door is three at most. And there is special sealing device on the discharging door to ensure the sealing reliable.

The revolution and rotation speed of the blades have been extensively studied and tested to give the mixer a high output without causing the segregation of materials with different grain size and weight. The movement of the material inside the trough is smooth and continuous. As shown in the picture,the blades track covers the whole bottom of the trough aftera cycle.

CO-NELE vertical planetary concrete mixer is of high quality, high efficiency, uniform mixing and no dead angle in mixing. It is used in building materials, concrete (dry hard, semi-dry hard, plastic concrete, UHPC ultra-high performance concrete, fiber concrete), refractory materials, chemicals, casting, metallurgy, ceramics, glass and other industries to solve the problem of high homogeneity of materials requiring mixing process.

Type | CMP50 | CMP100 | CMP150 | CMP250 | CMP330 | CMP500 | CMP750 | CMP1000 |

Output capacity(L) | 50 | 100 | 150 | 250 | 330 | 500 | 750 | 1000 |

Input capacity(L) | 75 | 150 | 225 | 375 | 500 | 750 | 1125 | 1500 |

Output weight(Kg) | 120 | 240 | 360 | 600 | 800 | 1200 | 1800 | 2400 |

Mixing power(Kw) | 3 | 5.5 | 7.5 | 11 | 15 | 18.5 | 30 | 37 |

Dischar ging power(Kw) | Pneumatic discharge(optional hydraulic) | |||||||

Planet/mixing arm | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 | |||

Paddle(nr) | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

DIscharging paddle(nr) | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

Weight(Kw) | 700 | 1100 | 1300 | 1500 | 2000 | 2400 | 3900 | 6200 |

Ligting power(Kw) | - | 2.2 | 2.2 | 3 | 4 | 4 | 7.5 | 11 |

Dimension(LxWxH,MM) | 950x790x1200 | 1670x1460x1450 | 1670x1460x1620 | 1860x1650x1780 | 1870x1870x1855 | 2230x2080x1880 | 2580x2340x2195 | 2890x2602x2220 |

Type | CMP1250 | CMP1500 | CMP2000 | CMP2500 | CMP3000 | CMP4000 | CMP4500 | CMP5000 |

Output capacity(L) | 1250 | 1500 | 2000 | 2500 | 3000 | 4000 | 4500 | 5000 |

Input capacity(L) | 1875 | 2250 | 3000 | 3750 | 4500 | 6000 | 6750 | 7500 |

Output weight(Kg) | 3000 | 3600 | 4800 | 6000 | 7200 | 9600 | 10800 | 12000 |

Mixing power(Kw) | 45 | 55 | 75 | 90 | 110 | 160 | 200 | 250 |

Dischar ging power(Kw) | 3 | 3 | 4 | 4 | 4 | 4 | 4 | 4 |

Planet/mixing arm | 2/4 | 2/4 | 3/6 | 3/6 | 3/9 | 3/9 | 3/9 | 3/9 |

Paddle(nr) | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

DIscharging paddle(nr) | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 2 |

Weight(Kw) | 6700 | 7700 | 9500 | 11000 | 12000 | 16500 | 17500 | 18500 |

Ligting power(Kw) | 15 | 15 | 22 | 30 | 37 | - | - | - |

Dimension(LxWxH,MM) | 3060x2760x2305 | 3230x2902x2470 | 3625x3230x2630 | 3900x3550x2695 | 3900x3550x2975 | 4560x4150x3105 | 4560x4150x3305 | 4560x4150x3305 |

CMP750 Precast Concrete Mixing Plant in Indones...

CMP750 Precast Concrete Mixing Plant in Indones...

If you have any questions, please leave a message, we will reply as soon as possible.

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.