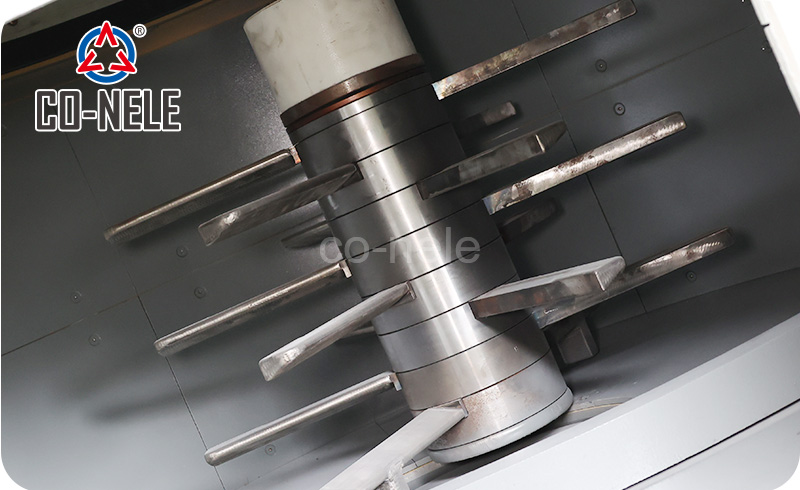

CO-NELE inclined intensive mixer use of reverse flow mixing principles can achieve the best hybrid uniformity in the shortest time.

[Function]Mixed,equalization,pinching,plasticizing,dispersing,granular,agglomeration,emulsification,covering,pulp,ball making,etc.

[Application]refractory materials,lithium batteries,ceramics,casting,metallurgy,environmental protection,building materials,chemical industry,compound fertilizer,.etc.

Advantages of Intensive Mixer

Optimized homogenization of process materials.

Shortest mixing times.

Excellent and stable product quality.

Low wear and maintenance.

Variable setup options for machine components and energy input range.

No demixing, even with ingredients of different densities.

Hybrid mixing processes with adjustable drives for the rotor and mixing pan.

Cost-effective operation and high mixing efficiency.

Reliable reproducibility in terms of product quality and batch times

The mixing pan can be arranged either horizontally or at an optimized angle of inclination to suit the particular requirements.

CO-NELLE intensive mixer includes equipment ranging from 5-10 liters (used in laboratories) to 3000 liters of inclined mixer capacity and 1000p-5000p horizontal intensive mixer. According to different needs, the mixing tray can be set horizontally or tilted at the optimal angle.

Higher tool speeds can be used for example to

optimally solubilize fibers

completely pulverize pigments

optimize mixing of fine fractions

manufacture suspensions with a high solid content

Medium tool speeds are used to

achieve mixtures with a high mixture quality

At lower tool speeds

lightweight additives or foams can be gently added to the mixture.

Higher tool speeds can be used for example to: - optimally solubilize fibers - completely pulverize pigments, optimize mixing of fine fractions - manufacture suspensions with a high solid content.

CO-NELE intensive mixers are designed as granulating and pelletizing mixers which produce predictable and reproducible grain sizes. Just one machine is needed to carry out the two process steps: mixing and granulating/pelletizing.

Type | CR02 | CR04 | CR05 | CR08 | CR09 | CRV09 | CR11 | CR15 | CRV15 | CR19 | CRV19 | CR24 | CRV24 |

In capacity(L) | 7.5 | 15 | 37 | 75 | 150 | 225 | 375 | 525 | 750 | 1125 | 1500 | 2250 | 3000 |

Out capacity(L) | 5 | 10 | 25 | 50 | 100 | 150 | 250 | 350 | 500 | 750 | 1000 | 1500 | 2000 |

Mixing device | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

Paddle | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

CO-NELE Inclined Intensive Mixer with a Wide Ap...

CO-NELE Inclined Intensive Mixer with a Wide Ap...

If you have any questions, please leave a message, we will reply as soon as possible.

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.