Refractory material

Permeable brick

Pavement brick

Prefabricated components

road

bridge

Cement concrete

Fiber concrete

SPECIFICATIONS FOR 250L PLANETERY CONCRETE MIXER | |||

planetary mixer | Out capacity(L) | L | 250 |

Input capacity(L) | L | 375 | |

Output mass(Kg) | kg | 1500 | |

Main performance parameters | Mixing power(Kw) | kw | 11 |

Dischar ging power(Kw) | kw | 3 | |

Lifting power(Kw) | kw | 3 | |

Internal structure | Pianet/main pianet(nr) | nr | 1/2 |

Paddle(nr) | nr | 1 | |

Discharging scrape(nr) | nr | 1 | |

Name: Hydraulic power station

Original: China shandong

A special designed hydraulic power unit is used to provide power for more than one discharging gates. On emergency, these discharging gates can be opened by hand.

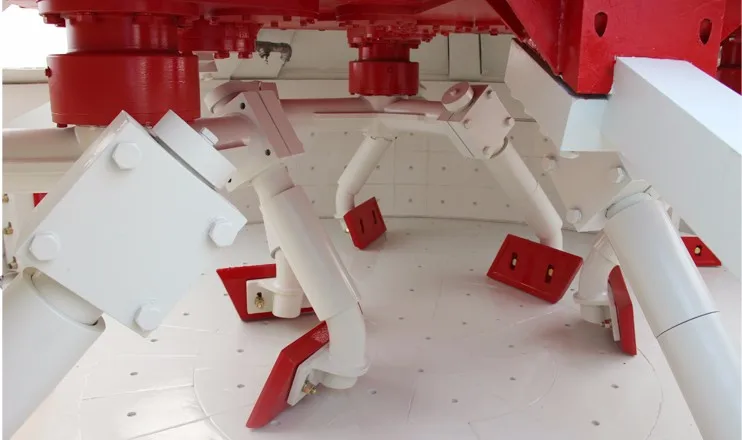

Name:Mixing device

Original: China shandong

Compulsory mixing is realized by composite moves of extruding and overturning driven by rotating planets and blades. Mixing blades are designed in parallelogram structure(patented), which can be turned 180°for reuse to increase service life. Specialized discharge scraper has been designed according to discharge speed in order to increase productivity.

Name: Discharging device

Original: China shandong

Domestic famous engines, strong driving force, low fuel consumption, high economic benefits 12F+4R sliding sleeve shift.

Name: Water spray pipe

Original: China shandong

The special designed sprayer is installed on the water pipe.The spraying water cloud can cover more area and also make the mixing more homogeneous.

.jpg)

Relying on the CO-NELE CR02 laboratory intensive mixing granulator (5 liters effective volume), through three batches of experiments, our technical team successfully granulated the raw material into uniform spherical particles with a particle size of 2-3

CONELE offers a full range of mixing equipment, from the small CEL1s laboratory mixer machine to the large CRV33 industrial machine, supporting various binder systems including ceramic, resin, and metal, and suitable for various abrasives such as corundum

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.