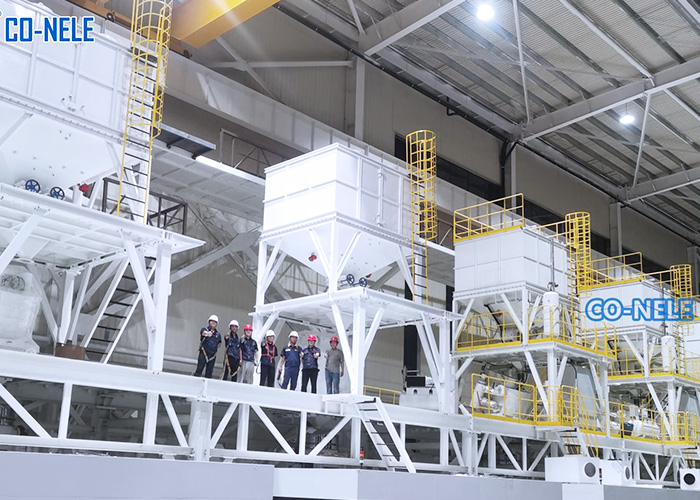

In today's rapidly developing industrial-grade 3D printing technology, the precision and efficiency of sand mold preparation have become key bottlenecks restricting industrial upgrading. CO-NELE six foundry sand mixer systems have been successfully installed and put into operation. These devices, with unparalleled mixing consistency and stability, provide crucial basic material support for industrial-grade 3D printing, enabling a smooth transition from traditional casting to digital manufacturing.

01 Core Technological Advantages

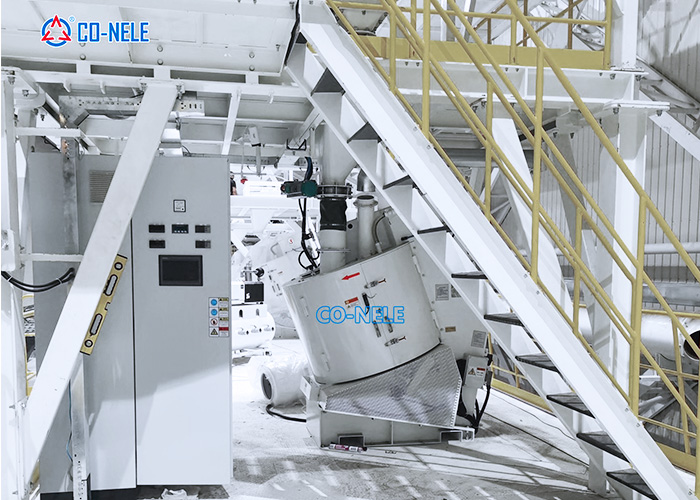

CO-NELE foundry sand mixers employ an inclined design, causing the molding sand and hardener to form complex movement trajectories during the mixing process. This significantly improves the strength and consistency of the sand mold, providing high-quality basic materials for 3D printing.

The equipment is equipped with advanced heating devices and stirring temperature sensors, enabling precise temperature control of the materials within the mixing tank. This innovation ensures that the sand reaches and maintains a constant temperature. Parts manufactured using this temperature-controlled sand meet stringent requirements for color difference, strength, and precision, and eliminate the need for a temperature-controlled workshop, greatly reducing production costs.

Flexible adjustability is another major highlight. The equipment can adjust its rotation speed according to the characteristics of the molding sand, and control the mixing time and intensity by adjusting the cylinder tilt angle, precisely adapting to different process requirements.

The integrated PLC control system achieves **full-process automation** from sand mixing to printing, supporting functions such as one-button start, automatic cleaning, and fault diagnosis, significantly reducing manual intervention.

02 Seamlessly Integrated Workflow The six foundry sand mixing machine systems are now perfectly integrated into the existing 3D printing workflow, forming a complete and efficient production chain.

*The workflow begins in the model design stage, where a 3D model of the sand mold is carefully designed using CAD software.

*The 3D model is then sliced to generate precise printing paths and parameters, preparing for actual printing.

*In the sand mixing stage, the CO-NELE sand mixer mixes sand particles and binder evenly in precise proportions, ensuring consistent and stable sand mixing quality.

*During the printing stage, the sand mold is printed layer by layer by the 3D printing system, with the binder precisely bonding the sand particles into shape.

*After printing, the sand mold is cured by a curing device to enhance its structural strength.

Finally, remove excess sand and binder from the sand mold surface, preparing it for casting.

03. Improved Quality and Efficiency

The deployment of the CO-NELE sand mixer significantly improves production efficiency and product quality, setting a new benchmark for industrial-grade 3D printing.

In terms of quality, the equipment can **uniformly mix** materials such as sand and binder, ensuring stable and consistent sand properties, thereby improving the quality of 3D printed sand molds.

Stable sand temperature and uniform mixing quality result in more consistent mold quality for each print, reducing mold defects and scrap rates caused by sand issues.

Efficiency improvements are equally significant. The equipment's precise material metering and efficient sand mixing function shorten mixing time, quickly providing qualified sand for 3D printing equipment.

Precise control of material usage avoids waste of sand and binder, reducing raw material costs.

Simultaneously, the high degree of automation reduces manual intervention, simultaneously lowering labor costs.

Back To The List

To address the need for highly homogeneous mixing and stable granulation in honeycomb zeolite production, this project selected the CO-NELE CRV24 honeycomb zeolite mixing and granulation machine as the core front-end process equipment.

CONELE intensive mixer can serve as core material processing equipment for environmental technology, supporting various processes ranging from industrial waste pretreatment, waste solidification, resource recovery, secondary fuel preparation to contaminat

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.