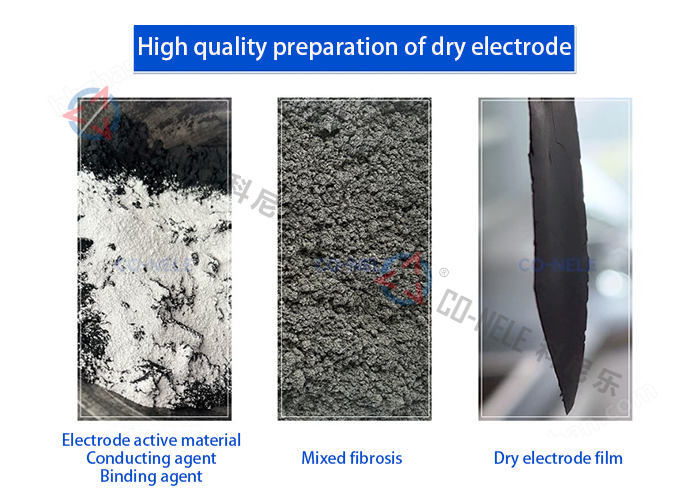

Dry electrode is an innovative process that presents new challenges for mixing equipment. Since powder materials are directly mixed in a solvent-free environment, how to ensure the uniformity of materials and protect their physical and chemical properties has become the core problem.

The mixing process of the dry electrode has a key impact on the film quality and electrochemical performance, this process is not only related to the uniform production of binder fiber, affecting the mechanical strength of the dry process film, but also plays a key role in the uniform distribution of the conductive agent, so as to effectively reduce the internal resistance of the electrode! It can be said that the mixing effect of raw materials and the degree of fibrosis at the front end of the process directly determine the final electrochemical performance and production cost of the dry electrode film. CONELE has extensive experience in the dry electrode industry, and the dry electrode mixers designed by CONELE are well equipped to meet these challenges due to their efficient mixing and high quality handling characteristics!

CONELE offers a full range of mixing equipment, from the small CEL1s laboratory mixer machine to the large CRV33 industrial machine, supporting various binder systems including ceramic, resin, and metal, and suitable for various abrasives such as corundum

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.