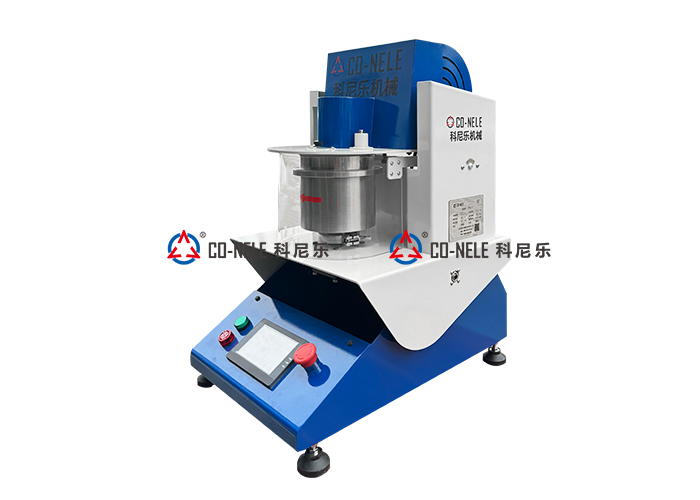

The CONELE CEL01 Laboratory intensive mixer has a mixing capacity of 1L, and the multi-functional mixing system can be used in many different applications, suitable for research and development and small-scale production areas, such as: mixing, granulation, coating, kneading, dispersion, dissolution, fiber separation, etc.

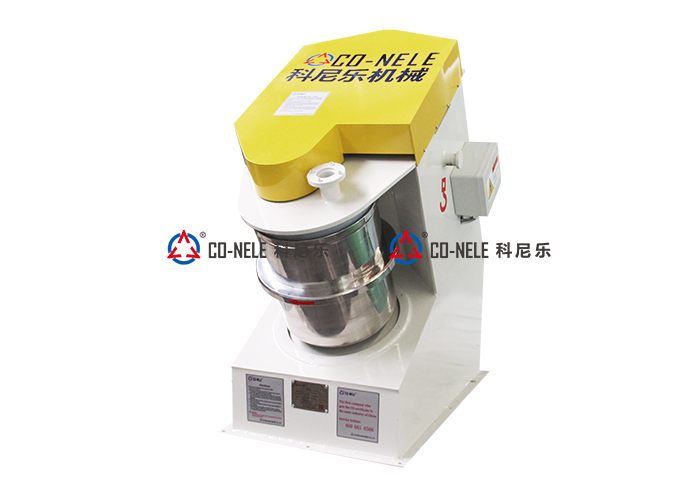

CEL5 laboratory intensive granulating mixer discharge capacity of 5L, manual discharge, lifting cylinder cap, inclined cylinder design, small models both mixing, granulation and other processes, is a multi-functional mixing granulation equipment.

The discharge capacity of CR02 laboratory intensive mixer is 5L, the electric tilting discharge, the optimized design Angle, the specific flow field of the mixed material is tilted up and down, the phenomenon of "anti-mixing" does not occur in the mixing cylinder, and the mixture with very high uniformity and good dispersion can be obtained, even if one thousandth of the additive can be evenly dispersed, and the mixing effect is good.

CONELE offers a full range of mixing equipment, from the small CEL1s laboratory mixer machine to the large CRV33 industrial machine, supporting various binder systems including ceramic, resin, and metal, and suitable for various abrasives such as corundum

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.