Capacity: 50-6000L

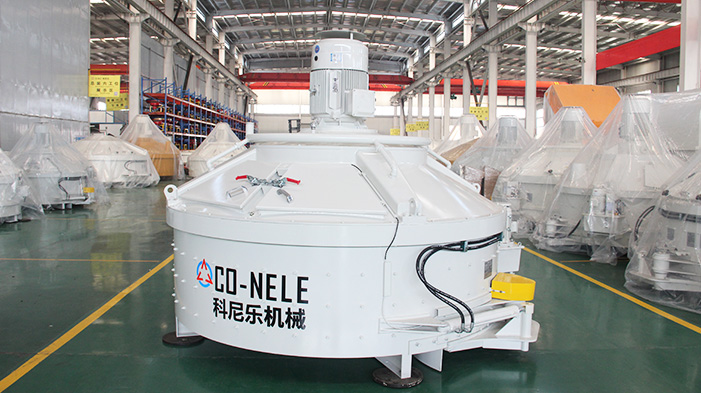

Intensive refractory mixer

The advantages of the intensive mixer in the field of refractory preparation are reflected in the wide applicability, uniform mixing, and high standard mixing preparation of refractory materials. Another feature of the intensive mixer is that the mixing and granulation process can be completed at the same time in the same equipment.

CONELE intensive mixer offers the following advantages:

1. Best mixing uniformity

2. Minimum mixing time

3. Flexibly adapt to a variety of refractory raw materials

4. Staggered mixing process: slow - fast - slow

Capacity: 1-2000L

Muller mixer

The muller mixer is a new mixing plant designed by CONELE for the refractory materials.

Advantages Of Muller Mixer:

*The best uniform mixture material

*The mixing efficiency is high,no dead angle

*Mixing material density and high porosity is small

*Structural repair less

*To maintain pressure relief function of doubleroller wheal device

*Thickening cylinder liner

Mixing capacity:500-2000kg

CONELE offers a full range of mixing equipment, from the small CEL1s laboratory mixer machine to the large CRV33 industrial machine, supporting various binder systems including ceramic, resin, and metal, and suitable for various abrasives such as corundum

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.