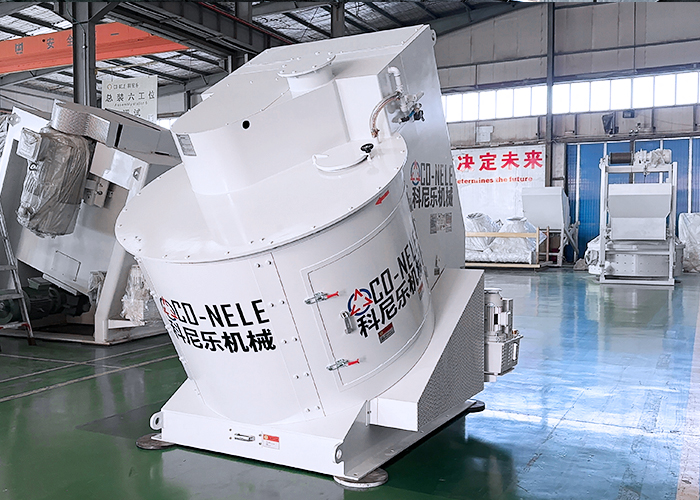

CR19 Intensive Mixer Structure:It is usually composed of the main machine,stirring device(high-speed flying rotor,side scraper),rotating body,transmission device,feed port,hydraulic center discharge port and other parts.The main machine is equipped with a friction lining.

CR19 Intensive Mixer Working principle:The high-speed flying rotor and the barrel rotate at the same time,so that the internal materials produce mutual friction and collision,thereby achieving mixing and homogenization.The friction lining can increase the friction force,which helps to improve the mixing efficiency and mixing uniformity.

Features:High mixing efficiency,can achieve efficient and uniform mixing of materials in a short time;can make each component material quickly and evenly mixed,the powder can be fully embedded in the fiber,without floc phenomenon;can effectively improve the particle distribution and uniformity of the material,and improve the overall performance of the material;can handle various types,different particle sizes and viscosities of materials,with strong adaptability.

Friction lining materials are used in automobile brake pads:

Reinforcement materials:metal fiber,organic fiber,inorganic fiber

Bonding materials:resin,rubber

Friction performance adjustment materials:friction-increasing materials(aluminum oxide,silicon carbide,potassium titanate crystals)

Graphite friction-reducing materials

Filling materials:carbonates,sulfates

Others:talcum powder,mica powder

CR19 friction lining material intensive mixer equipment technical parameters

| Model | MIXING VOLUME | DISCHARGING | BATCH | HEATING |

| CR19 | 330L-1000L | Hydraulic center unloading | - | - |

CONELE offers a full range of mixing equipment, from the small CEL1s laboratory mixer machine to the large CRV33 industrial machine, supporting various binder systems including ceramic, resin, and metal, and suitable for various abrasives such as corundum

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.