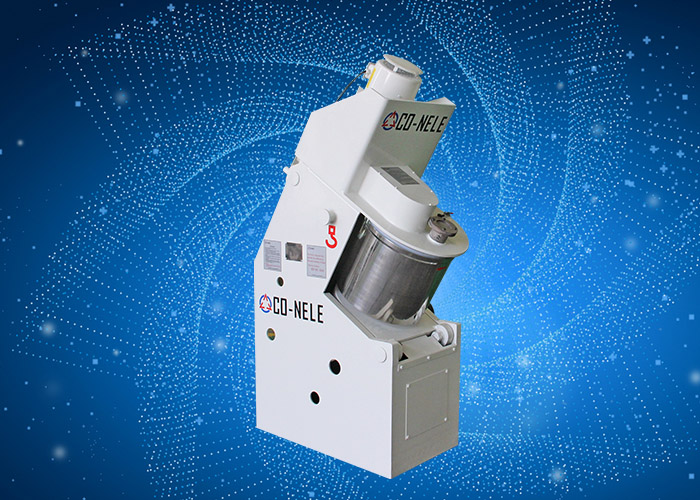

Intensive mixer is an efficient mixing equipment commonly used in industrial applications. Relying on the leading mixed granulation technology, it can meet the production requirements of lithium batteries, environmental protection, refractory materials, glass, metallurgy, building materials, casting sand and other production requirements, and can play a strong supporting role in the uniform mixing of materials.

The intensive mixer allows the polymer to melt completely in the cylinder through high-speed rotor operation, and quickly cycle to reach the forming temperature, mixing and forming.

CONELE offers a full range of mixing equipment, from the small CEL1s laboratory mixer machine to the large CRV33 industrial machine, supporting various binder systems including ceramic, resin, and metal, and suitable for various abrasives such as corundum

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.