Throughout the refractory industry, there have been strict quality requirements for raw material mixing. While traditional mixers have a significant market share, they often struggle to handle complex, high-end refractory materials. Refractory intensive mixers, on the other hand, have filled these gaps and become the industry's preferred choice.

To solve these stirring problems of traditional equipment, refractory intensive mixers, with their outstanding design and performance, have become an important tool in modern refractory material production:

Uniform mixing: High-shear mixers use advanced inclined design and efficient stirring systems to achieve thorough and uniform mixing, ensuring that each batch of material meets the highest quality standards.

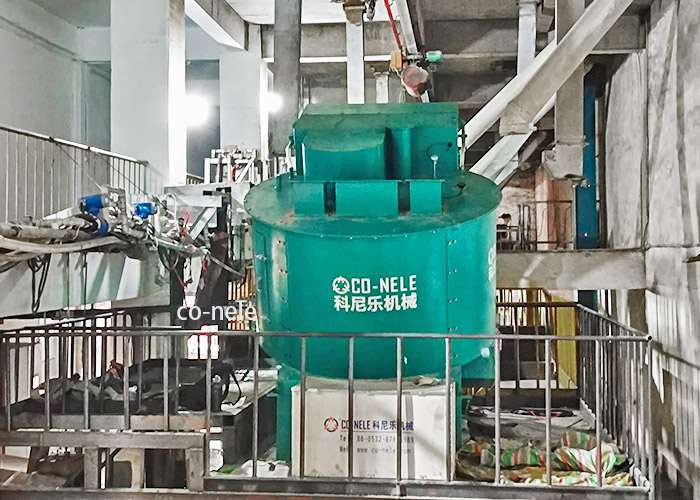

To address the need for highly homogeneous mixing and stable granulation in honeycomb zeolite production, this project selected the CO-NELE CRV24 honeycomb zeolite mixing and granulation machine as the core front-end process equipment.

CONELE intensive mixer can serve as core material processing equipment for environmental technology, supporting various processes ranging from industrial waste pretreatment, waste solidification, resource recovery, secondary fuel preparation to contaminat

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.