A rotating mixing disk tosses sand upward, while a high-speed rotor at an eccentric position reorganizes the material flow, coating each grain of sand with a uniform coating of bentonite within 90 seconds. This is a technological revolution taking place at a foundry on the outskirts of Istanbul.

In Istanbul's industrial district, a foundry supplying parts to European automakers was facing a common industry challenge: a casting defect rate hovering at 8% due to uneven sand mixing. Traditional sand mixers failed to fully activate the bentonite binder, resulting in fluctuating sand mold strength and a mountain of scrap in the workshop.

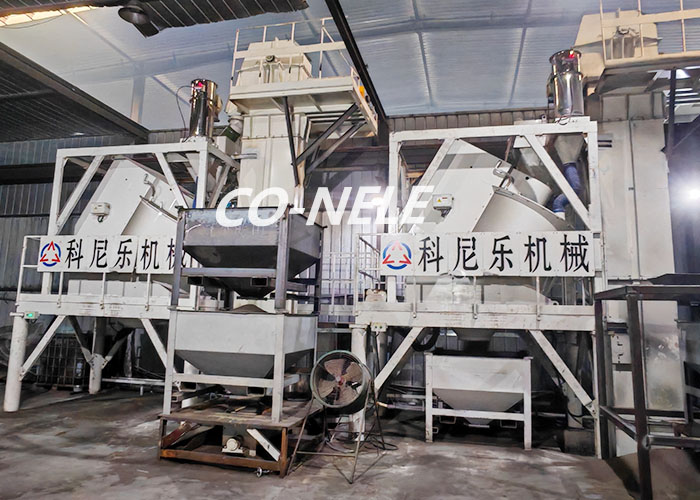

In early 2025, the plant introduced two CONELE CR11 high-Intensive mixers for foundry sand mixing. Within three months, the defect rate dropped to below 1.8%, while energy consumption was reduced by 40% and batch mixing time was shortened to one-third of that of traditional equipment.

Industry Pain Point: Inefficient Sand Mixing Technology Hinders Foundry Production

Turkey, Europe's fifth-largest producer of castings, produces over 2 million tons of foundry products annually. However, most foundries still use sand mixing technology from the past century, making sand preparation a bottleneck restricting quality and efficiency. The quality of bentonite-bonded molding sand directly determines the success or failure of castings. When the sand particles fail to evenly coat the bentonite, the sand mold lacks strength, making it prone to collapse or air holes during pouring.

Traditional sand mixing equipment suffers from three major pain points:

Dead corners in the mixing process: Approximately 30% of the sand is not fully incorporated into the mix, resulting in uneven binder distribution;

Inadequate bentonite activation: Low mechanical energy conversion efficiency prevents the binder from fully releasing its viscosity;

Imbalance between energy consumption and efficiency: A single batch of mixing takes as long as 5-8 minutes, accounting for over 40% of the entire sand processing plant's energy consumption.

A manager at a Turkish foundry once admitted, "With over 200 tons of molding sand processed daily, every 1% increase in scrap rate means tens of thousands of dollars in losses." This industry dilemma has become the driving force behind technological innovation, including the triple breakthrough design of the CR11 intensive sand mixer.

When the Turkish customer selected two RC11 high-performance intensive sand mixers, they essentially chose a solution that reshaped the physical process of sand mixing. The core of CONELE's sand mixing technology lies in overturning the traditional single-dimensional mixing model, achieving a thorough reorganization of the sand material through a three-dimensional energy field.

Counterflow dynamics: The core design of the CR11 utilizes counter-rotating mixing discs and high-speed rotors. The mixing discs rotate at a specific angle, conveying the sand material upward in a waterfall flow. Simultaneously, the eccentrically positioned rotors cut the material flow at speeds of up to 240 rpm.

This high-speed differential generates shear forces four times greater than those of conventional sand mixers, ensuring that bentonite particles are fully deagglomerated.

Zero-dead-angle guarantee system: The bottom scraper acts as a third motion component, continuously cleaning the inner wall of the mixing disc. This eliminates the problem of material compaction, a major concern for foundries, ensuring that 99% of the sand material is effectively mixed.

The equipment's unique zero-dead-angle design reduces discharge residue rates to less than 0.2%, significantly reducing cross-contamination between batches.

Intelligent energy management: The operator can independently adjust the mixing disc and rotor speeds based on the sand material characteristics. Kaolin sand is processed in low-speed mode (rotor speed 100 rpm), while silica sand formulations utilize high-speed mode (240 rpm).

This flexibility allows the same equipment to meet the molding sand preparation needs of various casting processes, including cast iron, cast steel, and aluminum alloys.

To address the need for highly homogeneous mixing and stable granulation in honeycomb zeolite production, this project selected the CO-NELE CRV24 honeycomb zeolite mixing and granulation machine as the core front-end process equipment.

CONELE intensive mixer can serve as core material processing equipment for environmental technology, supporting various processes ranging from industrial waste pretreatment, waste solidification, resource recovery, secondary fuel preparation to contaminat

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.