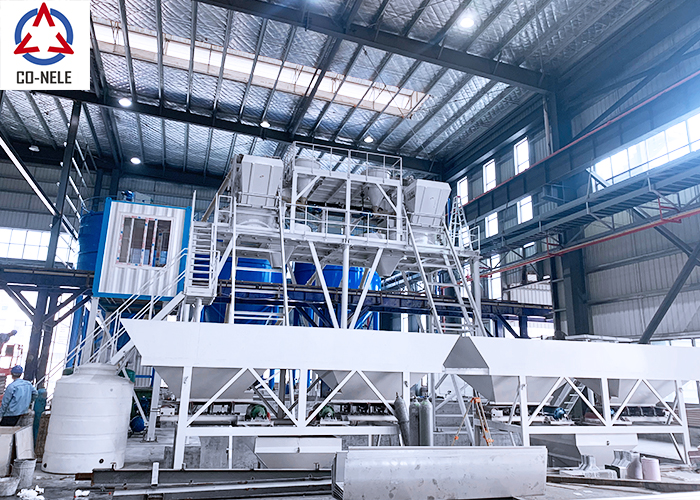

This UHPC precast component production line is equipped with two CMP500 planetary concrete mixers. The entire production line includes a batching system, a loading system, a mixing system, and a molding system.

The two CMP500 planetary concrete mixers achieve comprehensive coverage through the principle of rotation and revolution, and there is no dead angle in material mixing. UHPC is of reliable quality and can effectively improve its quality in bridge paving and product preparation.

Productivity

Type CMP50 CMP100 CMP150 CMP250 CMP330 CMP500 CMP750 CMP1000 Output capacity(L) 50 100 150 250 330 500 750 1000 Input capacity(L) 75 150 225 375 500 750 1125 1500 Output weight(Kg) 120 240 360 600 800 1200 1800 2400 Mixing power(Kw) 3 5.5 7.5 11 15 18.5 30 37 Dischar ging power(Kw) Pneumatic discharge(optional hydraulic) Planet/mixing arm 1/2 1/2 1/2 1/2 1/2 Paddle(nr) 1 1 1 1 1 1 1 1 DIscharging paddle(nr) 1 1 1 1 1 1 1 1 Weight(Kw) 700 1100 1300 1500 2000 2400 3900 6200

To address the need for highly homogeneous mixing and stable granulation in honeycomb zeolite production, this project selected the CO-NELE CRV24 honeycomb zeolite mixing and granulation machine as the core front-end process equipment.

CONELE intensive mixer can serve as core material processing equipment for environmental technology, supporting various processes ranging from industrial waste pretreatment, waste solidification, resource recovery, secondary fuel preparation to contaminat

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.