LATEST NEWS & CASES

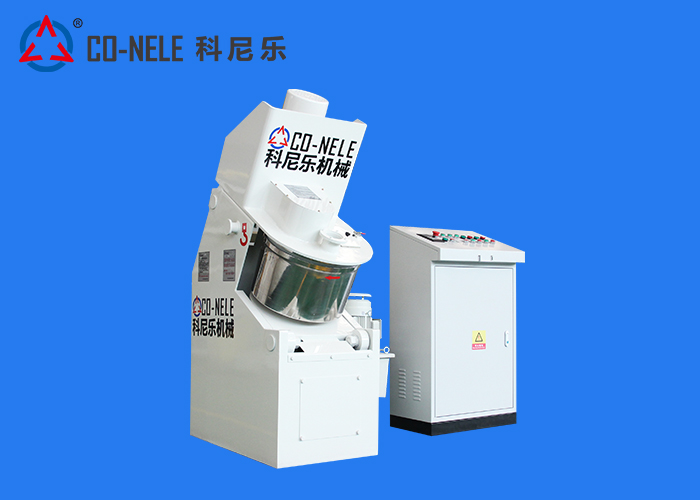

CRV15 mixing granulator can fully granulate bentonite, with high particle granulation rate, high energy utilization rate and good equipment quality.

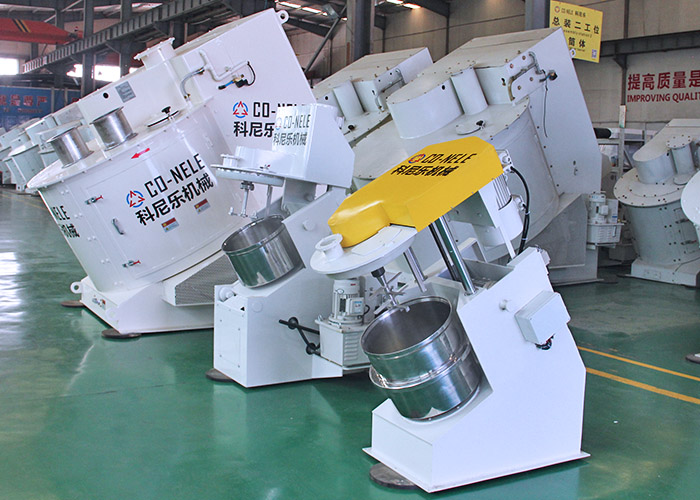

The company's CR series intensive mixer has the advantages of ideal mixing effect and good performance.

In the refractory industry product field intensive mixing granulator can provide professional technical support and industry experience.

The problems that need to be solved in the production of PC stone bricks are the density, strength, surface imitation stone effect, quality and output of the product.

Precast concrete mixer is mainly used in the mixing of floor tile bottom material, block brick, PCCP pipe, subway pipe section, high-speed rail sleeper, PC wall panel, pipe pile and other products.

Laboratory granulator through the scientific mixed granulation process, the raw materials are fully mixed, and then made into the specified size of the mixed material.

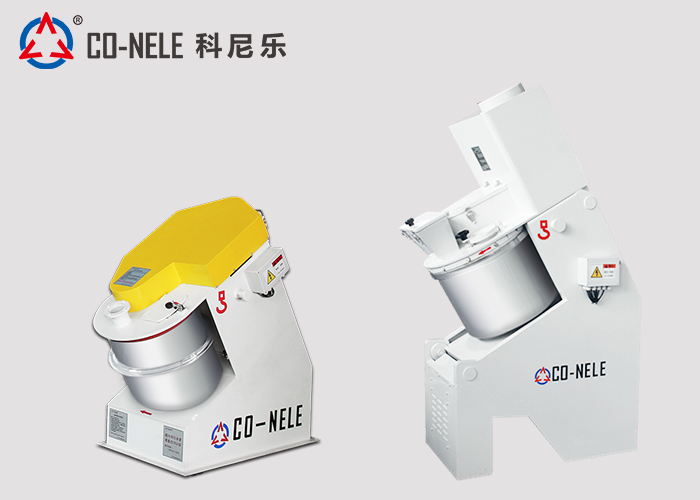

CR small size (lab use) mixing granulator for cement/soil applications has strong granulation process performance and can granulate powder materials or fine particles.

How does the CR laboratory intensive mixer operate?

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.