LATEST NEWS & CASES

For granulation processes in different production areas, the CR02 laboratory granulator offers you high performance granulation.

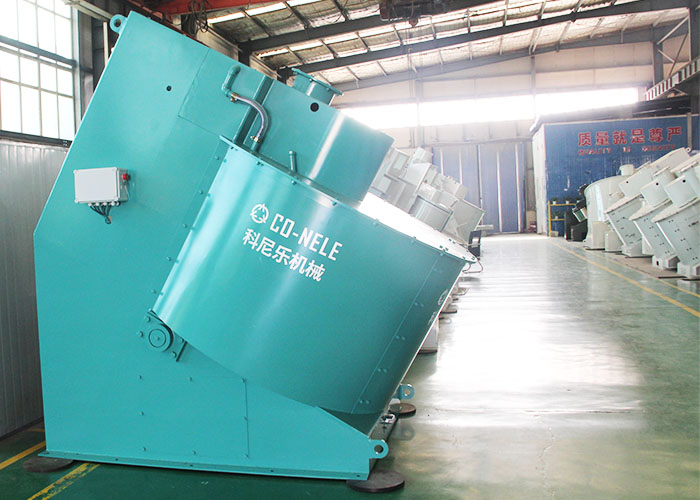

CONELE CR Type Intensive Mixer for Sand Lime Brick

CONELE intensive mixer has many advantages in the production of carbon-silicon anode materials for lithium batteries.

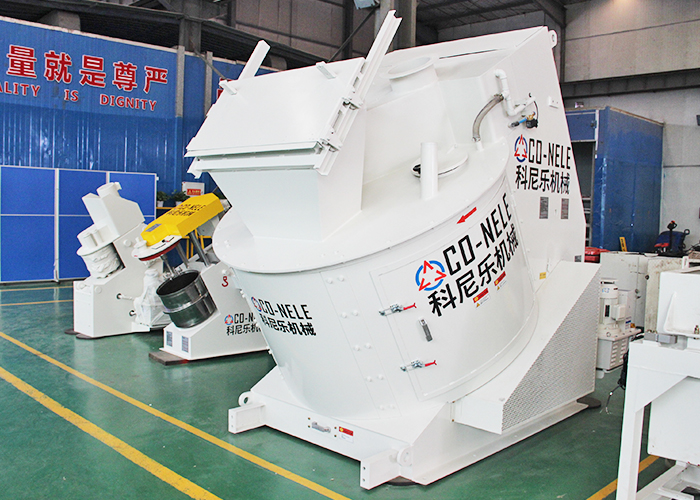

Zinc Oxide Granulator - Inclined Mixing Granulator

The incline pan counter current intensive mixer adopts intelligent design, fine mixing according to different processes, the whole treatment process is efficient, stable, no dust pollution.

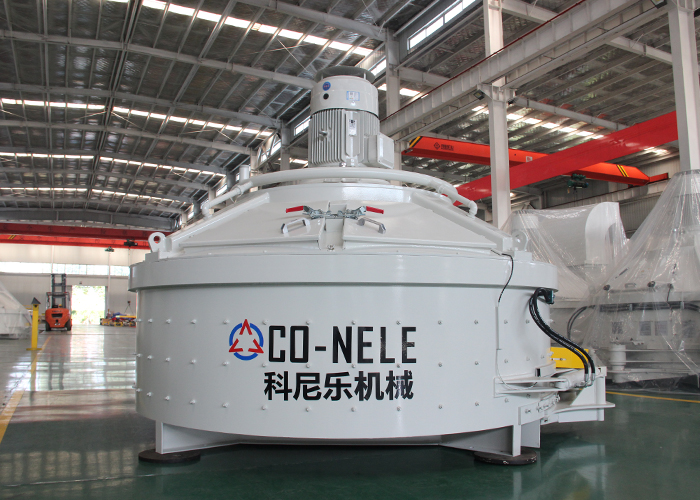

The planetary mixer has the advantages of reasonable design, stable operation, convenient maintenance and low maintenance cost.

Precast concrete mixer has strong function and high material quality, so it can play its advantages in more fields.

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.