LATEST NEWS & CASES

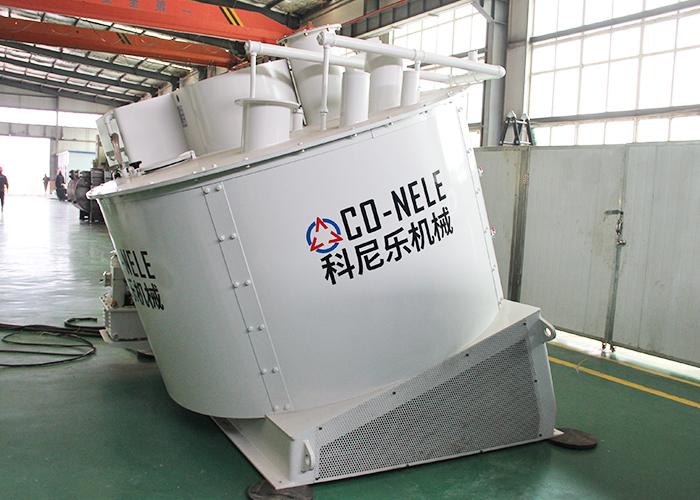

Intensive mixer can add heating and vacuum function according to different requirements.

Intensive sand mixer can carry out various process requirements of sand mixing work, the use of various binder types are not restricted.

Refractory castable mixer processing process without dead angle, discharge clean without dead angle.

Alloys and minerals pelletizing mixers use the following operating principle: The rolling process is used to convert fine particles into larger particles by triggering the action of binding forces

CONELE intensive mixer is suitable for paste section in lead-acid battery production.

The fertilizer mixer can control the action time, solubility and particle stability of the fertilizer by packing the hydrophobic agent and mineral in a targeted way.

Molecular sieve mixed pelletizing machine through a certain tilt Angle and unique pelletizing disk to complete the material mixing, pelletizing dual tasks.

Intensive mixer is suitable for new sintering machine, old sintering machine renovation project and steel mill dust, sludge recovery and utilization

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.