A 2000L planetary concrete mixer and a 1000L ultra-high-performance concrete (UHPC) mobile mixing plant have been successfully commissioned and are now in operation on a precast concrete production line specifically designed for manufacturing precast interior wall panels. This project aims to meet the stringent requirements of modern precast construction, where high material consistency, a stable production rhythm, and flexible batching are crucial.

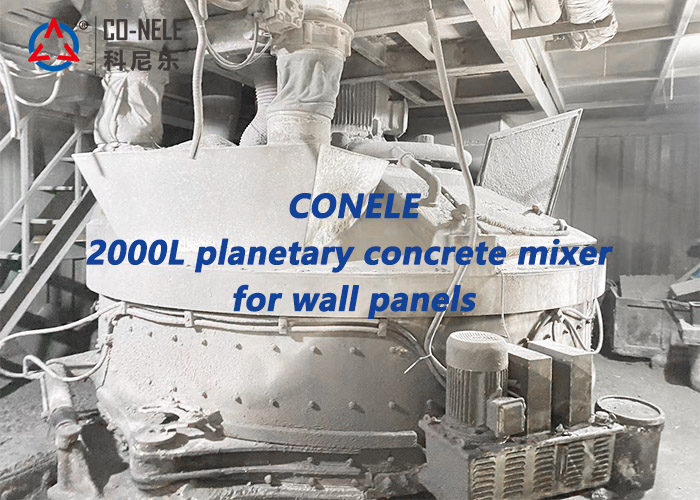

At the heart of the system is the CONELE planetary concrete mixer, which utilizes a planetary mixing principle to deliver superior mixing performance. The multi-trajectory mixing motion ensures uniform mixing of cement, aggregates, additives, and fibers in a short time, effectively eliminating dead zones and segregation. This high level of mixing uniformity directly contributes to improved surface quality, enhanced structural integrity, and consistent mechanical properties of the finished precast wall panels.

The combination of the UHPC mobile mixing plant and the planetary concrete mixer provides a balanced solution that combines high production capacity with operational flexibility. Its mobile configuration allows the production line to efficiently switch between different mix designs and production schedules, supporting the production of both standard precast components and higher-specification products without compromising efficiency.

To address the need for highly homogeneous mixing and stable granulation in honeycomb zeolite production, this project selected the CO-NELE CRV24 honeycomb zeolite mixing and granulation machine as the core front-end process equipment.

CONELE intensive mixer can serve as core material processing equipment for environmental technology, supporting various processes ranging from industrial waste pretreatment, waste solidification, resource recovery, secondary fuel preparation to contaminat

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.