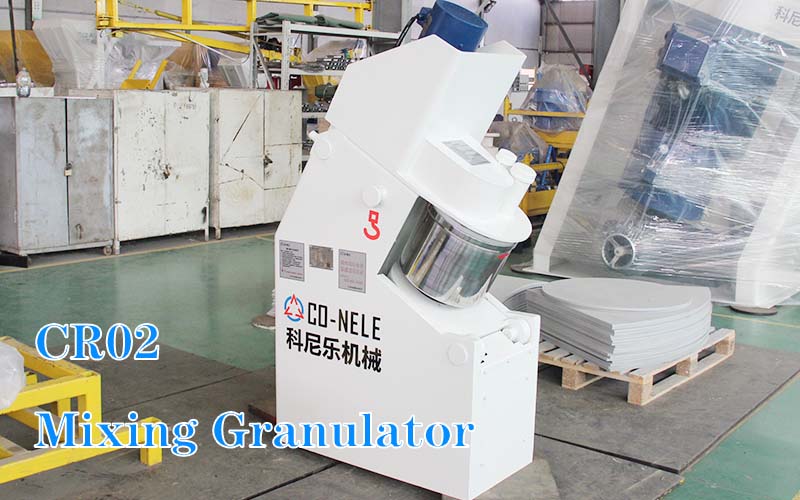

5L Mixer Granulator Machine: The barrel is installed at an angle, usually equipped with a stirring granulating disk, stirring paddle or stirring rotor. This design helps the material to form a complex flow pattern during the mixing and granulating process, achieving efficient mixing and granulation. The three-dimensional turbulent flow technology is used inside the equipment to achieve a higher mixing uniformity in a shorter time. By adjusting the parameters such as the speed of the stirring component, the tilt angle, and the amount of material input, the size, shape and distribution characteristics of the particles can be precisely controlled.

| Model | Granulation volume | Granulating disc | Paddle | Discharging | Batch |

| CEL05 | 2L-5L | 1 | 1 | manual discharge | Batch |

| CR02 | 2L-5L | 1 | 1 | Automatic unloading | Batch |

Precise experiment: The 5-liter capacity is suitable for small-batch, high-precision ceramic powder mixing and granulating experiments in the laboratory, which is convenient for researchers to accurately control various parameters such as material ratio, temperature, stirring speed, etc., to obtain ideal granulation effects, providing data support and process reference for large-scale production.

Cost saving: Compared with large-scale production equipment, the 5-liter laboratory granulator has lower costs in terms of energy consumption and material input, which can reduce experimental costs and reduce losses caused by experimental failures.

https://youtu.be/b-bApc_8ijw?si=IVB5R_gldCJTAx5C

Strong adaptability: It can process various types of ceramic raw materials, including powders of different particle sizes and chemical compositions, and can also adapt to materials of different viscosities. At the same time, the parameters and processes of the equipment can be flexibly adjusted according to different production needs to produce ceramic particles that meet various requirements.

CONELE offers a full range of mixing equipment, from the small CEL1s laboratory mixer machine to the large CRV33 industrial machine, supporting various binder systems including ceramic, resin, and metal, and suitable for various abrasives such as corundum

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.