The CO-NELE granulating mixer is specifically designed for the precision preparation of powder materials such as sintered fluxes. It integrates enhanced mixing and uniform granulation, achieving stable particle morphology and high uniformity in the laboratory or production line, providing reliable assurance for subsequent sintering processes.

The sintered flux granulation mixer employs an optimized impeller structure and adjustable operating parameters, efficiently completing wet mixing, granulation, and discharge processes. Its compact laboratory-grade design is ideal for material formulation development, pilot testing, and process verification, and is widely used in the research and development of welding materials, metallurgical powders, and new materials.

Key features of the sintered flux granulation mixer:

* Integrated mixing and granulation design, high efficiency and stable performance

* Adjustable speed and time to meet different process requirements

* Uniform particle distribution and good repeatability

* Easy cleaning, facilitating multi-formulation testing

* Experimental data can be directly scaled up to production line applications

Typical applications of the sintered flux intensive mixer:

* Preparation of sintered flux powder

* Mixing of metal and alloy powders

* Research and development of flux and functional materials

CO-NELE provides integrated mixing and granulation solutions from experimental to production, helping customers achieve efficient and controllable sintered flux preparation processes.

Back To The List.jpg)

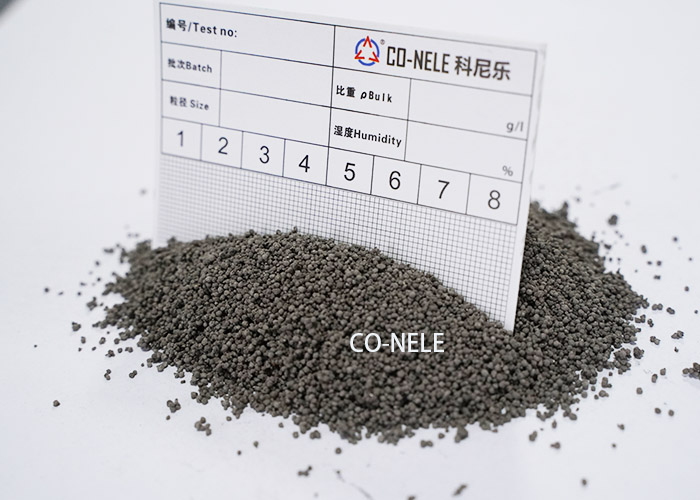

Relying on the CO-NELE CR02 laboratory intensive mixing granulator (5 liters effective volume), through three batches of experiments, our technical team successfully granulated the raw material into uniform spherical particles with a particle size of 2-3

CONELE offers a full range of mixing equipment, from the small CEL1s laboratory mixer machine to the large CRV33 industrial machine, supporting various binder systems including ceramic, resin, and metal, and suitable for various abrasives such as corundum

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.