The lithium-ion graphene material granulator is a device used to make lithium-ion graphene materials into granules. The following is a detailed introduction for you:

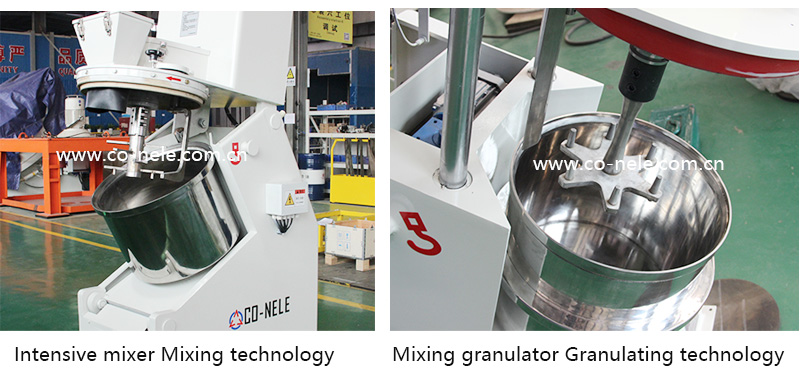

Intensive granulator mixer Working principle:

Inclined design of mixing container

The mixing container is inclined at a certain angle, which is conducive to the flow and tumbling of materials during the mixing process. When the mixer is working, the materials will slide down along the inclined container wall under the action of gravity, and will be continuously mixed by the mixing device.

The inclination angle can be adjusted according to different material characteristics and mixing requirements to achieve the best mixing effect. Generally speaking, the inclination angle between 30° and 60° is more common.

It is suitable for a variety of lithium-ion graphene materials, with high granulation efficiency and relatively uniform particle shape and size.

Market situation: With the rapid development of the lithium battery industry, the demand for lithium battery graphene material granulators is also growing.

At present, CO-NELE provides granulator equipment of various types and specifications. The performance, efficiency and automation of granulators are also constantly improving to meet the lithium battery industry's demand for high-quality electrode materials.

Back To The List

To address the need for highly homogeneous mixing and stable granulation in honeycomb zeolite production, this project selected the CO-NELE CRV24 honeycomb zeolite mixing and granulation machine as the core front-end process equipment.

CONELE intensive mixer can serve as core material processing equipment for environmental technology, supporting various processes ranging from industrial waste pretreatment, waste solidification, resource recovery, secondary fuel preparation to contaminat

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.