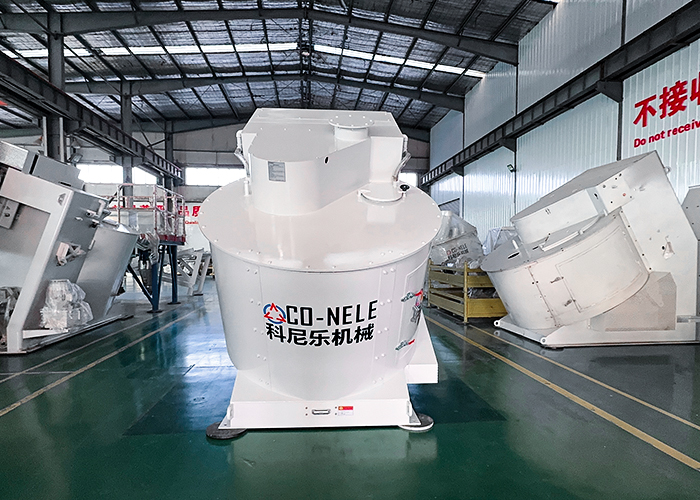

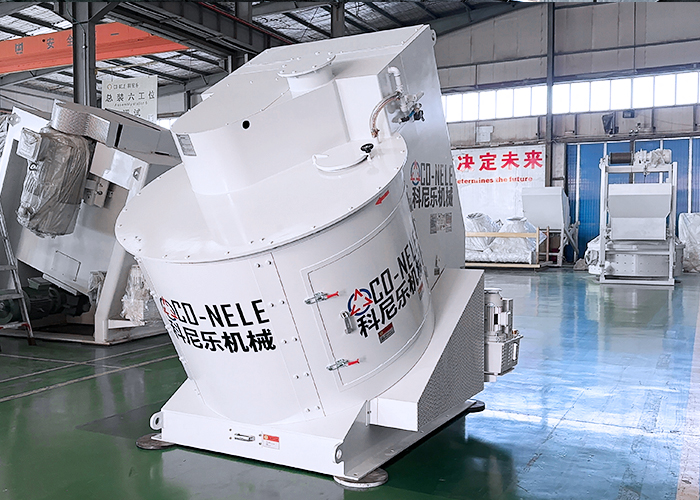

CO-NELE intensive mixers are designed as granulating and pelletizing mixers which produce predictable and reproducible grain sizes.

Just one machine is needed to carry out the two process steps:mixing and granulating/pelletizing.

Technical advantages of CO-NELE mixing granulator

High spheroidization rate, uniform particle size, good particle shape and strong particle density

Rotary mixing drum and granulation tool set are controlled by variable frequency, the speed can be adjusted, the particle size can be controlled by adjusting the speed, and the particle size can be adjusted online

Unloading method Tipping unloading or bottom unloading (hydraulic control), quick and clean unloading, easy to clean

A complete range of models, from small laboratory (5-10L) granulation to large industrial pelletizing, can meet the needs

It has a wide range of applications and can meet the mixing needs of different industries and various materials

Granulator application industry

ceramics

Molding materials, molecular sieves, proppants, varistor materials, dental materials, ceramic tools, abrasive materials, oxide ceramics, grinding balls, ferrites, etc.

building materials

Porous media of bricks, expanded clay, perlite, etc., refractory ceramsite, clay ceramsite, shale ceramsite, ceramsite filter material, ceramsite brick, ceramsite concrete, etc.

Glass

Glass powder, carbon, leaded glass frit, waste glass slag, etc.

metallurgy

Zinc and lead ore, alumina, carborundum, iron ore, etc.

chemical

Slaked lime, dolomite, phosphate fertilizers, peat fertilizers, mineral materials, sugar beet seeds, fertilizers, phosphate fertilizers, carbon black, etc.

Environmental friendly

Cement filter dust, fly ash, sludge, dust, lead oxide, fly ash, slag, dust, etc.

Carbon black, metal powder, zirconia