MBP series mobile batching plant is researched, designed and produced independently by our company using European advanced technology, preassembled, prewiring, compact structure, easy relocation and environment friendly.

Item | Type | |||||

MBP08 | MBP10 | MBP15 | MBP20 | |||

Output(theoretical) | m3/h | 30 | 40 | 60 | 80 | |

Discharging Height | mm | 4000 | 4000 | 4000 | 4000 | |

Mixer Unit | Dry filling | L | 1125 | 1500 | 2250 | 3000 |

Output | L | 750 | 1000 | 1500 | 2000 | |

Mixing power | kw | 30 | 37 | 30*2 | 37*2 | |

weighing and feeder skip | Drive power | kw | 11 | 18.5 | 22 | 37 |

Medium speed | m/s | 0.5 | 0.5 | 0.5 | 0.5 | |

Capacity | L | 1125 | 1500 | 2250 | 3000 | |

Weighing precision | % | ±2 | ±2 | ±2 | ±2 | |

Cement weighing system | Capacity | L | 325 | 425 | 625 | 850 |

Weighing precision | % | ±1 | ±1 | ±1 | ±1 | |

Liquid weighing systemS | Capacity | L | 165 | 220 | 330 | 440 |

Water weighing precision | % | ±1 | ±1 | ±1 | ±1 | |

Admixture weighing precision | % | ±2 | ±2 | ±2 | ±2 | |

Cement screw conveyor | External | mm | Φ168 | Φ219 | Φ219 | Φ273 |

Speed | t/h | 20 | 35 | 35 | 60 | |

Power | kw | 5.5 | 7.5 | 7.5 | 11 | |

Control mode | Automatic | Automatic | Automatic | Automatic | ||

Power | kw | 53 | 69 | 97 | 129 | |

Weight | T | 15 | 18 | 22 | 30 | |

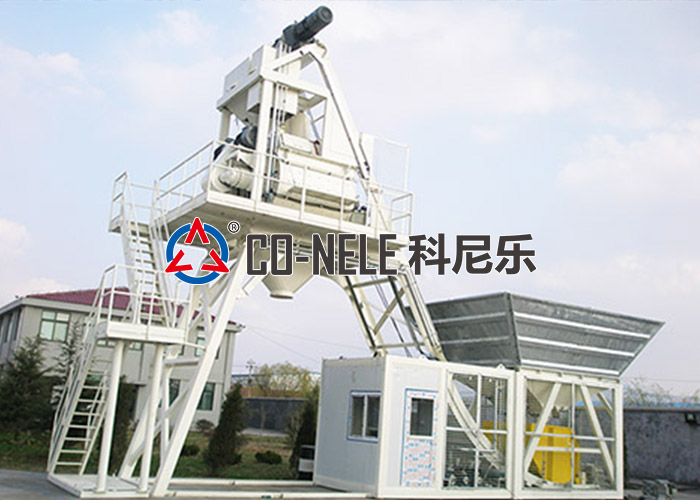

MBP series mobile batching plants are milestone of concrete batching plant, which is researched, designed and produced independently by our company using European advanced technology for reference.

MBP series batching plant is a pre-wired and pre-assembled mobile batching plant that has been engineered in order to meet the growing requirements of reducing time and space on the site. Its compact structure allows the immediate passage from the transport configuration to the operational one.

MBP series plants consist of the following components: mixing platform, concrete mixer, aggregate storage hoppers, aggregate weighing system, aggregate skip hoist, water weighing system, cement weighing system, control cabin and so on. All components connect each other to form an independent equipment convenient to transport, assembling and test.

MBP series plants are applicable to all types of ready- mix concrete and concrete precast production.

Apply to the mixers

MBP series batching plants apply to the following mixers: twin-shaft mixer JS1500/1000, JS2250/1500, JS3000/2000, or planetary mixer MP1500/1000, MP2250/1500.

_副本.jpg)

Weighing system

The weighing of water, aggregates and cement takes place separately, simultaneously and with autonomous and independent phases through load cells applied to supports that ensure the biggest

Additives can be loaded together with water.

Aggregates storage

The aggregate storage capacity is from

The mixing group

The mixing group is the heart of the MBP batching plant: the MP planetary mixer and the JS twin-shaft mixer can mix various types of top quality concretes with continuous process control.

Pre- wiring

The MBP series batching plant is completely pre-wired in order to meeting the requirements of speed, versatility and compactness. This operating solution sensibly reduces the plant installation and commissioning times.

The control cabins is connected with the main frame work together. Control panel is installed in the cabin. All the equipment is trial run before delivered. It needn't disconnect and connect the cables.

The compressor is connected with the main framework together also. It needn't disconnect and connect when they are transported.

Feeder skip

The skip, fitted with a gravity discharge gate, rests on a rail along which a weighing system is installed. Through this device, the aggregates are weighed and transported into the mixer.

Control system

Co-nele control system is the ideal means to automate the standard operation of the concrete batching plants. His architecture is flexible, versatile and structured mainly for the operating management of the process of ready-mix concrete. Thanks to a friendly-user interface, the system can be utilized with utmost simplicity by non-qualified personnel. The aim is to enable the operator to autonomously manage the whole plant with the utmost safety. The personalized configuration and the operating automation together with the economy of the Co-nele control system allow to meet the customer's specific requirements in reducing times.

Configuration

The hardware standard configuration includes high precision batching meters, management and monitoring system (PLC), an operator terminal with functional keyboard and LCD display, an application-oriented/operating software available in English and Chinese languages, on request, a printer.

To address the need for highly homogeneous mixing and stable granulation in honeycomb zeolite production, this project selected the CO-NELE CRV24 honeycomb zeolite mixing and granulation machine as the core front-end process equipment.

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.