When selecting between Planetary Mixers and Intensive Mixers for Ultra-High Performance Concrete (UHPC), the choice depends on factors like mixing efficiency, material viscosity, scalability, and process requirements.

Recommendations for UHPC

1. Planetary Mixers are preferred for:

- Precision mixing of fiber-reinforced UHPC to avoid fiber damage.

- Small-to-medium batches requiring vacuum processing (e.g., removing air bubbles) .

2. Intensive Mixers are better for:

- Large-scale production with ultrafine additives requiring rapid dispersion.

- Highly abrasive UHPC formulations needing wear-resistant equipment .

3.Working principle

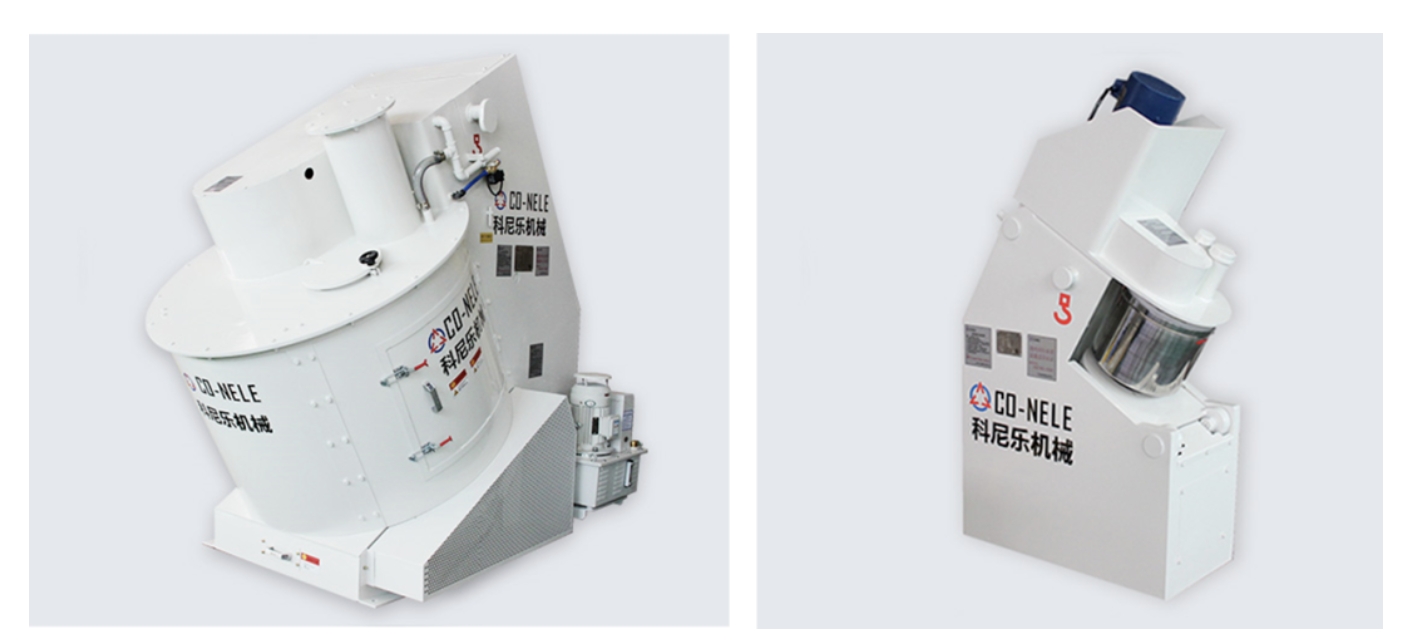

Planetary mixer: The mixing tool rotates around its own axis and revolves around the central axis of the mixing container, forming a planetary motion trajectory. This mode of motion enables the mixing arm and blades to mix the materials in three-dimensional space, and can achieve mixing without dead angles.

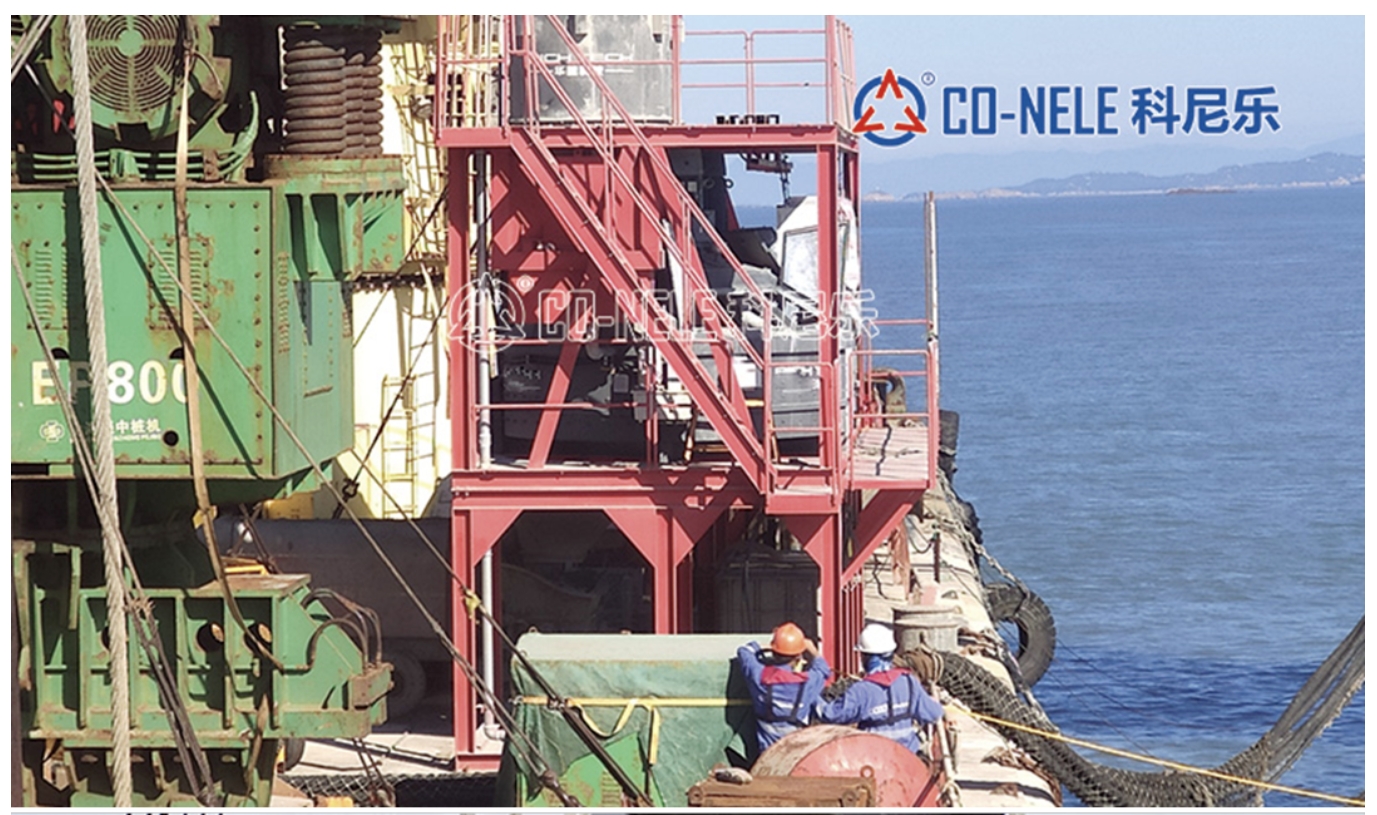

Intensive Mixer: Usually adopts a mixing structure such as a propeller or turbine, with high speed and strong shear force as the main features. Through the high-speed rotation of the mixing blades, the materials form a strong vortex and shearing effect in the mixing container, and the materials are quickly mixed.

4.Mixing effect

High uniformity: The unique planetary motion can ensure that various components such as cement, mineral admixtures, steel fibers, etc. in UHPC are evenly dispersed, avoiding fiber agglomeration, making the performance of UHPC more stable.

Good fiber dispersion: It has a good dispersion effect on difficult-to-mix components such as steel fibers, which can ensure that the fibers are evenly distributed in concrete, thereby effectively improving the mechanical properties of UHPC.

Fast mixing: Relying on strong shear force and vortex, materials can be quickly mixed in a short time. For materials such as UHPC that require efficient production, it can improve production efficiency.

Good overall uniformity: It can make the material achieve a high uniformity on a macro scale, but when dealing with special components such as fibers, it may not be as fine as the planetary mixer in terms of fiber dispersion effect.

5.Applicable material characteristics

Planetary mixer

Strong adaptability: It can adapt to UHPC materials of different proportions, whether it is high flow or high viscosity UHPC, it can achieve good mixing effect.

Handling complex formulas: It can handle materials from fine powder to rolled materials, as well as materials with large specific gravity differences, and is suitable for complex formulas such as UHPC containing a variety of different materials and fibers.

Intensive Mixer

High-viscosity materials: When handling highly viscous UHPC materials, it can effectively overcome the viscous resistance of the material and achieve good mixing with strong power and shear force.

Large production demand: For large-scale production of UHPC, and where there are high requirements for the efficiency and uniformity of material mixing, a high-powered mixer can better meet the production needs of large production volumes.

6. Cost and Energy Consumption

Planetary Mixers

-Planetary mixer, low price, uniform mixing, high mixing efficiency

Intensive Mixers

- Higher energy input for high shear rates but faster mixing times.

- Cost-effective for large-scale operations requiring rapid homogenization .

7.Material Compatibility

Planetary Mixers

- Excel with high-viscosity pastes and doughs, such as UHPC’s dense, fiber-reinforced mixtures.

- CONELE planetary mixers ensure homogeneity in modern concrete blends, critical for UHPC’s strength .

Intensive Mixers

- Better suited for materials requiring rapid energy transfer and particle breakdown. The CONELE CR intensive mixer high shear rates ensure even distribution of ultrafine additives like silica fume .

Back To The List

CONELE offers a full range of mixing equipment, from the small CEL1s laboratory mixer machine to the large CRV33 industrial machine, supporting various binder systems including ceramic, resin, and metal, and suitable for various abrasives such as corundum

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.